Marine API Line Pipes

[Search Related Products]

Marine API Line Pipes

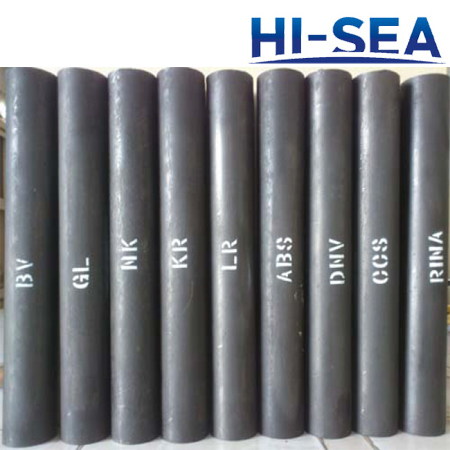

Marine API line pipes are a sort of marine steel pipes certified by leading classification societies. They are applied to convey gas, water, oil. The marine API line pipes are manufactured according to the standard API SPEC 5L. In addition the above-mentioned pipes, we are able to supply other line pipes in line with GB/T 9711. We provide you a broad range of specifications: O.D. 168.3 ~ 323.9mm, W.T. 5.2 ~ 28.83mm. These pipes are plain-end. Of course, if you have any specific requirements, we are able to customize pipes for you. We are engaged in providing best quality products with reasonable price for our customers. If you trust us, we will build a pleasant cooperative relationship!

Chemical Composition %

|

Adopted Standard |

Steel Grade |

C |

Si |

Mn |

P |

S |

V |

Nb |

Ti |

Other |

CE¢òw |

CEpcm |

||||||

|

Max |

Max |

Max |

Max |

Max |

Max |

Max |

Max |

|

Max |

Max |

||||||||

|

API SPEC 5L |

PSL1 |

|||||||||||||||||

|

A |

0.22 |

- |

0.90 |

0.030 |

0.030 |

- |

- |

- |

|

|

|

|||||||

|

B |

0.28 |

- |

1.20 |

0.030 |

0.030 |

a,b |

a,b |

b |

|

|

|

|||||||

|

X42 |

0.28 |

- |

1.30 |

0.030 |

0.030 |

b |

b |

b |

|

|

|

|||||||

|

X46 X52 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

b |

b |

b |

|

|

|

|||||||

|

PSL2 |

||||||||||||||||||

|

BR BN |

0.24 |

0.40 |

1.20 |

0.025 |

0.015 |

a |

a |

0.04 |

c |

0.43 |

0.25 |

|||||||

|

X42R X42N |

0.24 |

0.40 |

1.20 |

0.025 |

0.015 |

0.06 |

0.06 |

0.04 |

c |

0.43 |

0.25 |

|||||||

|

X46N |

0.24 |

0.40 |

1.40 |

0.025 |

0.015 |

0.05 |

0.05 |

0.04 |

b,c |

0.43 |

0.25 |

|||||||

|

X52N |

0.24 |

0.45 |

1.40 |

0.025 |

0.015 |

0.07 |

0.07 |

0.04 |

b,c |

0.43 |

0.25 |

|||||||

|

Note |

A.Unless otherwise agreed, the sum of the niobium and vanadium contests shall be ¡Ü0.06%. B.The sum of the niobium, vanadium and titanium concentrations shall be ¡Ü0.25%. C.Unless otherwise agrees, 0.05% maximum for copper, 0.30% maximum for nickel, 0.30% maximum for chromium and 0.15% maximum for molybdenum. |

|||||||||||||||||

Mechanical Properties

|

Adopted Standard |

Steel Grade |

Yield Strength |

Tensile Strength |

Elongation % |

||||

|

MPa |

MPa |

|||||||

|

API SPEC 5L |

PSL1 |

|||||||

|

A |

¡Ý210 |

¡Ý335 |

See table 6 and 7 of API SPEC 5L |

|||||

|

B |

¡Ý245 |

¡Ý415 |

||||||

|

X42 |

¡Ý290 |

¡Ý415 |

||||||

|

X46 |

¡Ý320 |

¡Ý435 |

||||||

|

X52 |

¡Ý360 |

¡Ý460 |

||||||

|

PSL1=2 |

||||||||

|

|

Min. |

Max. |

Min. |

Max. |

||||

|

BR BN |

245 |

450 |

415 |

760 |

||||

|

X42R X42N |

290 |

495 |

415 |

760 |

||||

|

X46N |

320 |

525 |

435 |

760 |

||||

|

X52N |

360 |

530 |

460 |

760 |

||||

|

Note |

For pipes required longitudinal testing, the maximum yield strength shall be ¡Ü495MPa(71800psi). |

|||||||

Marine API Line Pipes

Marine API Line Pipes