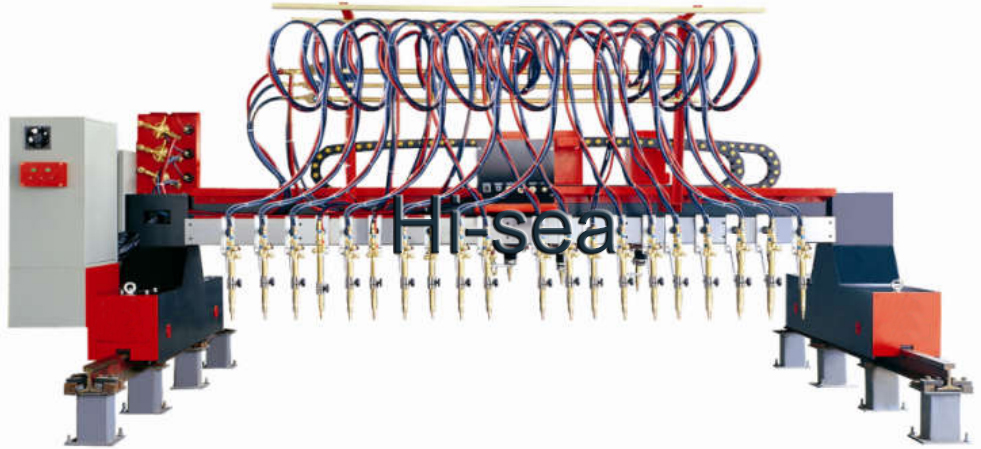

Single Side Driven CNC Flame Cutting Machines

[Search Related Products]

Single side driven CNC flame cutting machine

1.Cutting method and principle£º

Flame cutting is oxygen cutting in which the appropriate part of the material to be cut is raised to ignition temperature by an oxyfuel gas flame. Also known as oxy-fuel cutting, the process is used for separating and shaping steel components.

2.Application of range and usage£º

Normally, the flame cutting is recommended to cut more than 5mm carbon steel, because this kind of steel plate has small thermal deformation. Stainless steel and nonferrous metals cannot be used flame cutting, Stainless steel on heated surface oxidized high density layer prevents thermal down, thus affecting the plate fuse; Strong ability to non-ferrous metals such as copper and aluminum heat sink, resulting in cutting surface heat is quickly lost, also affects the plates fusing. Normal cutting can be divided into 5-100mm and 5-300mm, special specification can be customized

3.Machine Technical Parameters:

|

Type |

Track Span |

Effective cutting length |

Effective cutting width |

Drive system |

Traveling speed |

|

Single side driven |

2500-4000mm |

Rail length deduct 3000mm |

1500-3000mm |

AC servo drive |

¡Ü6000mm/min |

Note: the travelling speed can be customized to 24000mm/min according to customer need.

4.Flame Cutting Parameters:

|

Type |

Cutting gas |

Cutting speed |

Cutting Thickness |

|

Single-sided driven |

O2/Natural gas/etc. |

100-750mm/min |

6mm-300mmm |

Note: The special specification can be customized and cutting thickness can be achieved 600mm.