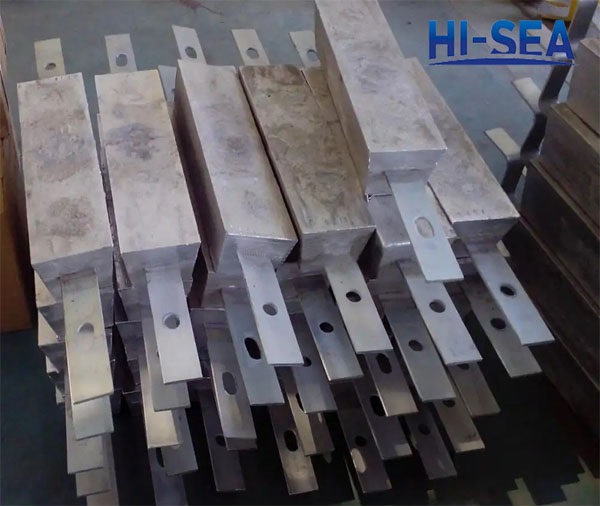

Bracelet Type Aluminum Anode

[Search Related Products]

Bracelet Type Aluminum Anode

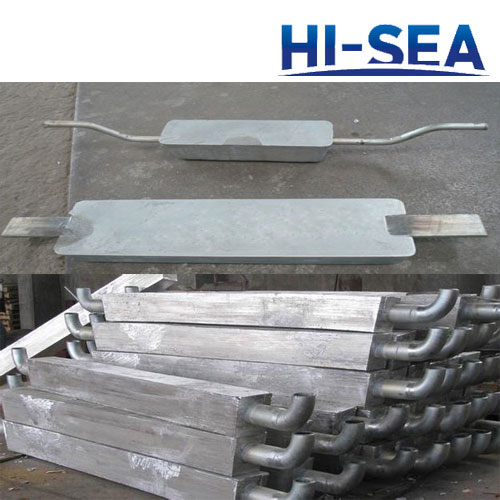

The most commonly used aluminum alloy anodes are Al-Zn-In series and Al-Zn-Hg series, applicable to the cathodic protection of ships, ports and marine facilities in seawater, sea water cooling system and reservoir deposited water site and other construction.

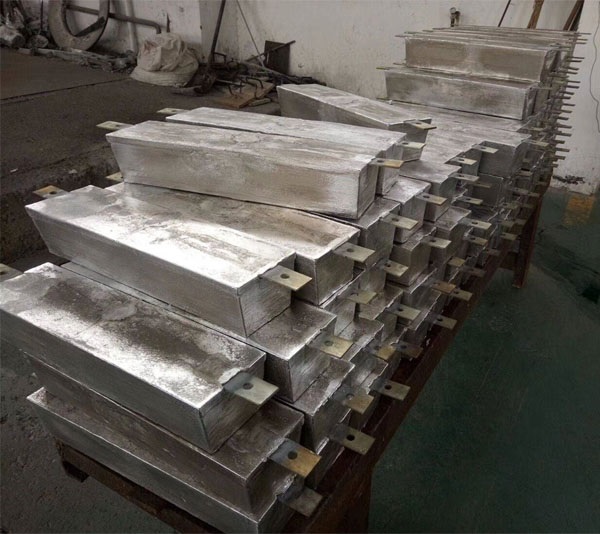

Aluminum zinc indium system (AZI) sacrificial anode is casted by high purity aluminum, zinc, indium and other metal alloy. Aluminum alloy anode is produced in line with the implementation of GB4948-2002 Aluminum Zinc Indium Alloy Sacrificial Anode.

The aluminum alloy anode can prevent the corrosion of steel structure in seawater, widely used for the anti-corrosion of the ship hull, pressurized water tank, seawater pipeline, port and terminal facilities, marine engineering, drilling platform, condensator and pipelines in soil. The performance of aluminum anode is influenced by the chemical composition of the alloy, so we offer different composition of aluminum alloys to meet our customer requirements.

Implementing Standard

GB/T 4950-2002

Main Performance

low driving voltage; light weight; high current efficiency.

Application

Bracelet type aluminum sacrificial anode is used for the anti-corrosion cathodic protection of the projects of oil, gas, water supply and drainage pipeline, underground cable, chemical industry, communication, harbor, ship, reservoir gate and other projects operating in fresh water.

Specifications of Bracelet Type Aluminum Anode

Specification: Inside Diameter*Width*Thickness* Interval

mm

Weight

kg/pair

Iron Core Specification

mm

¦µ1020¡Á200¡Á35¡Á51

68

5¡Á50

¦µ819¡Á60¡Á30¡Á51

13

5¡Á25

¦µ624¡Á80¡Á30¡Á51

17

5¡Á50

¦µ513¡Á100¡Á30¡Á51

17

5¡Á50

¦µ487¡Á200¡Á45¡Á51

41

5¡Á50

¦µ470¡Á480¡Á25¡Á51

50

5¡Á50

¦µ436¡Á480¡Á38¡Á51

70

5¡Á50

¦µ420¡Á413¡Á45¡Á51

69

5¡Á50

¦µ385¡Á150¡Á59¡Á51

32

5¡Á50

¦µ335¡Á505¡Á38¡Á51

56

5¡Á50

¦µ280¡Á250¡Á45¡Á51

29

5¡Á50

¦µ252¡Á250¡Á45¡Á51

26

5¡Á50

Bracelet Type Aluminum Anode