High Silicon Cast Iron Anode

[Search Related Products]

![]()

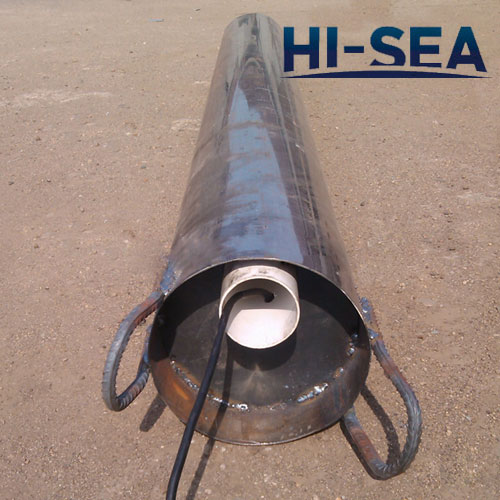

High Silicon Cast Iron Anode

The high silicon cast iron anode with chromium is the ideal auxiliary anode for the impressed current cathodic protection system. It is widely used for the protection and anti-corrosion of underground or underwater metal structures such as oil, natural gas, chemical plants ans water company. Our high silicon cast iron anode is manufactured according to the GB8491-87 standard.

Types

Various types of rod and tubular high silicon cast iron anodes are available.

Implementing Standard

SYJ36-89

Main Performance

Extremely strong acid corrosion resistance; widely used auxiliary anode material for impressed current cathodic protection system.

Main Application

Widely used for the impressed current cathodic protection in offshore oil drilling platforms, underground pipes, underground cables and other facilities.

Product Features

1. Low consumption rate, allowing large current density;

2. Small grounding resistance, stable polarization potential and high utilization rate.

Chemical Composition

|

Product Name |

Chemical Element (%) |

Impurity Content (%) |

|||||

|

Si |

Cr |

Mn |

C |

Fe |

P |

S |

|

|

High Silicon Cast Iron |

14~16 |

- |

0.6~0.8 |

0.8~1.05 |

margin |

¡Ü0.25 |

¡Ü0.1 |

|

Ferrochrome Silicon |

14~16 |

4.0~4.5 |

0.6~0.8 |

0.8~1.05 |

margin |

¡Ü0.25 |

¡Ü0.1 |

Electrochemical Performance

|

Product Name |

Use Environment |

Working Current Density (A/m2) |

Consumption Rate (kg/A.a) |

|

High Silicon Cast Iron |

In seawater |

50 |

0.3~1.0 |

|

Ferrochrome Silicon |

In fresh water/soil |

10 |

0.05~0.2 |

Specifications and Sizes

Number

Specification mm

Weight kg

Anode Cable

Section mm2

Length mm

1

¦µ50¡Á1500

22

25

1000

2

¦µ75¡Á1200

40

25

1000

3

¦µ75¡Á1500

90

25

1000

Instructions

1. The high silicon cast iron anode has high silicon content so avoid crashing during the transportation and installation. The anode wire should not be used as lifting tool during the installation so as to avoid the increasing of the joint resistance and the damage of the lead wire and anode break away.

2. High silicon cast iron anode should be installed at the place where the protection current distribution is uniform. When installed in soil, the coke should be used as filler and has less than max. 15mm particle diameter.

3. The distance between high silicon cast iron anode and pipe is 50m to 300m.

4. The distance from the ground of high silicon cast iron anode in either vertical or horizontal installation should be no less than 1 meter; generally the distance between every two vertical anodes is 3m, and the interval between two horizontal anodes which are arranged as a line is 0.3m to 1m.

5. When high silicon cast iron anode is used with the corrosion protection device, the anode connection instrument belongs to positive pole and the protected body connection instrument belongs to negative pole.

High Silicon Cast Iron Anode