Marine Calorifier

[Search Related Products]

1. Brief Description

High quality with pump type or without pump type Marine Calorifier supply.

The power can be steam and electric.

The quality have approved by IMO. Such as CCS, ABS, BV, EC, GL class.

The material usually be carbon steel or stainless steel.

We are also the navy supplier.

2. DRG Series Electrical Calorifier (with or without pump type)

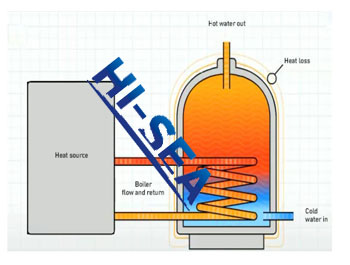

The type calorifier is suitable for heating fresh water on the ship or platform, heated fresh water for crew use.

|

Type |

DRG- |

||||

|

0.12 |

0.2 |

0.3 |

0.5 |

1 |

|

|

Capacity(m3) |

0.12 |

0.2 |

0.3 |

0.5 |

1 |

|

Working Pressure (MPa) |

0.4 |

||||

|

Design Pressure (MPa) |

0.44 |

||||

|

Testing Pressure (MPa) |

0.66 |

||||

|

Safety Valve Open Pressure (MPa) |

0.42 |

||||

|

Water Inlet Temp. (°„C) |

15 |

||||

|

Water Outlet Temp. (°„C) |

65 |

||||

|

Hot-water capacity (kg/h) |

180 |

360 |

540 |

720 |

900 |

|

Electric Heating Power (kw) |

12 |

24 |

36 |

48 |

60 |

|

The laying of outer surface of insulation layer thickness (mm) |

40 |

||||

|

Outsourcing galvanized steel sheet thickness (mm) |

0.7 |

||||

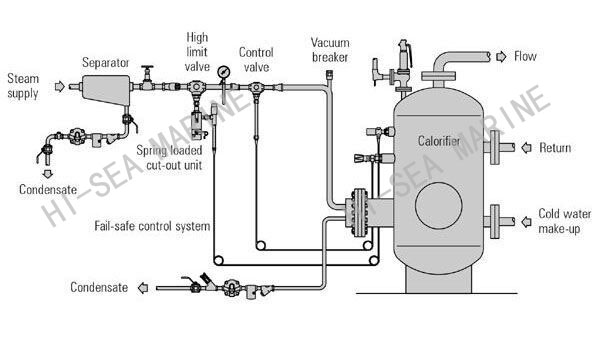

3. ZRG Series Steam Calorifier (with or without pump type)

This series calorifier can be combined to use with hydrophore on board, that is to use fresh water or sea water in hydrophore to replenish this tank, and then heated by steam heating elements for usage of entire vessel.

Temperature adjusting valve: open and close it according to the set temperature control range.

Pressure gauge: to show the pressure in tank.

Thermometer: to show the water temperature in tank.

Safety valve: If the pressure in tank is more than 0.63MPa, the safety valve will open to release the pressure in tank.

Note: Never wind the raw material belts into the inlet of safety valve when installing the safety valve.

|

Model |

ZRG- |

||||

|

0.12 |

0.2 |

0.3 |

0.5 |

1.0 |

|

|

Capacity £®m3£© |

0.12 |

0.2 |

0.3 |

0.5 |

1.0 |

|

Working pressure£®MPa£© |

0.6£®60°ś£© |

||||

|

Design pressure £®MPa£© |

0.7 |

||||

|

Test pressure £®MPa£© |

1.05 |

||||

|

Safety valve open pressure£®MPa£© |

0.63 |

||||

|

Water inlet temperature£®°ś£© |

15 |

||||

|

Water outlet temperature £®°ś£© |

65 |

||||

|

Working temperature £®°ś£© |

0~65 |

||||

|

Design temperature£®°ś£© |

80 |

||||

|

Steam pressure £®MPa£© |

0.3 |

||||

|

Heating water capacity£®kg/h£© |

275 |

450 |

750 |

1200 |

3250 |

|

steam consumption£®kg/h£© |

27.5 |

45 |

75 |

120 |

325 |

|

The thickness of the external thermal layer£®mm£© |

40 |

||||

|

The thickness of outer galvanized sheet steel£®mm£© |

0.7 |

||||

4. ZDR Steam and Electrical Calorifier (with or without pump type)

This calorifier can be combined to use with hydrophore on board, that is to use water in hydrophore to replenish this tank, and then heated by electric or steam heating elements for usage of entire vessel.

|

Model |

ZDR- |

||||

|

0.12 |

0.2 |

0.3 |

0.5 |

1.0 |

|

|

Capacity£®m3£© |

0.12 |

0.2 |

0.3 |

0.5 |

1.0 |

|

Working pressure£®MPa£© |

0.4£®60°ś£© |

||||

|

Design pressure£®MPa£© |

0.44 |

||||

|

Test pressure£®MPa£© |

0.68 |

||||

|

Safety valve open pressure£®MPa£© |

0.42 |

||||

|

Water inlet temperature£®°ś£© |

15 |

||||

|

Water outlet temperature£®°ś£© |

65 |

||||

|

Working temperature£®°ś£© |

0~65 |

||||

|

Design temperature£®°ś£© |

80 |

||||

|

Steam pressure £®MPa£© |

0.3 |

||||

|

Heated water capacity£®kg/h£© |

275 |

450 |

750 |

1200 |

3250 |

|

Steam consumption £®kg/h£© |

27.5 |

45 |

75 |

120 |

325 |

|

Heated water capacity£®kg/h£© |

180 |

360 |

540 |

720 |

900 |

|

Electrical heating power£®kW£© |

12 |

24 |

36 |

48 |

60 |

|

Electricity |

AC380/50Hz/3¶’, AC440V/60Hz/3¶’(Optional) |

||||

|

The thickness of the external thermal layer£®mm£© |

40 |

||||

|

The thickness of outer galvanized sheet steel£®mm£© |

0.7 |

||||

5. Exhibition Hall

A. without pump type calorifier

B. with one pump type calorifier

C. with double pumps type calorifier

6. Kinds of IMO certificate supply: