Galvanic Anode

[Search Related Products]

Galvanic Anode

Galvanic anode is also called 'sacrificial anode', is used to protect the hulls of ships, water heaters, pipelines, distribution systems, above-ground tanks, underground tanks, and refineries. The anodes in sacrificial anode cathodic protection systems must be periodically inspected and replaced when consumed.

Classified by Usage:

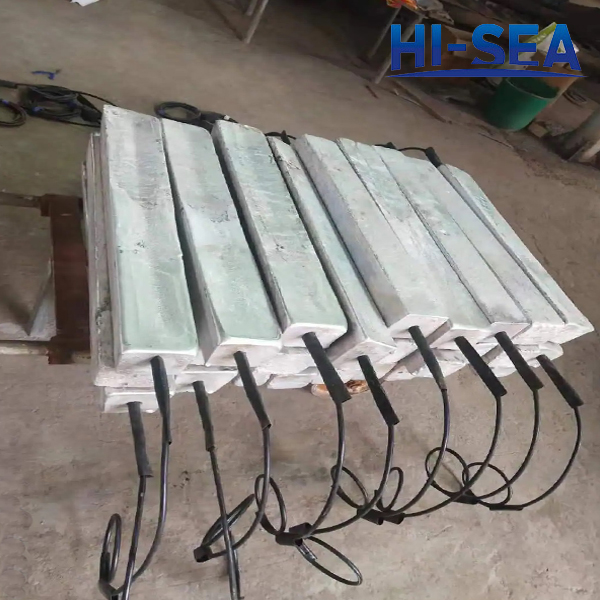

1. Welding Type Sacrificial Anode for Ship Hull (Single Iron Foot)

2. Welding Type Sacrificial Anode for Ship Hull (Double Iron Foot)

3. Bolt Connection Type Sacrificial Anode for Ship Hull

4. Sacrificial Anode for Ballast Water Tank

5. Sacrificial Anode for Offshore Engineering Facilities

6. Sacrificial Anode for Harbor Engineering Facilities

7. Strip Shape Sacrificial Anode for Seawater Cooling System

8. Disc Shape Sacrificial Anode for Seawater Cooling System

9. Sacrificial Anode for Storage Tank

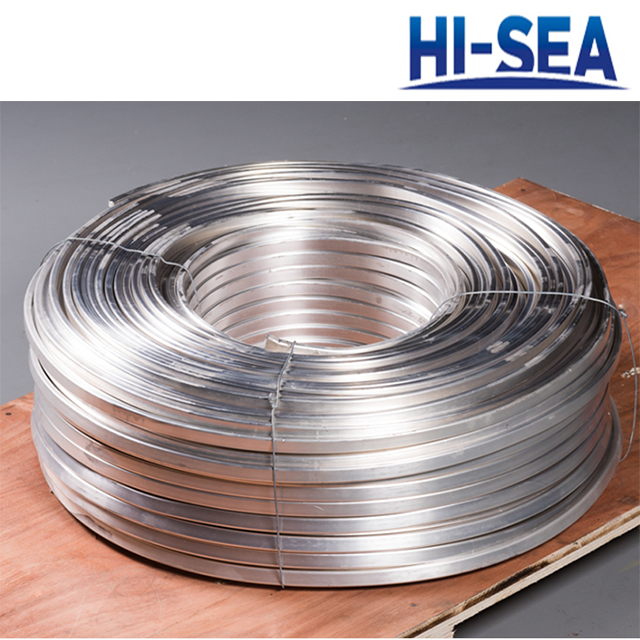

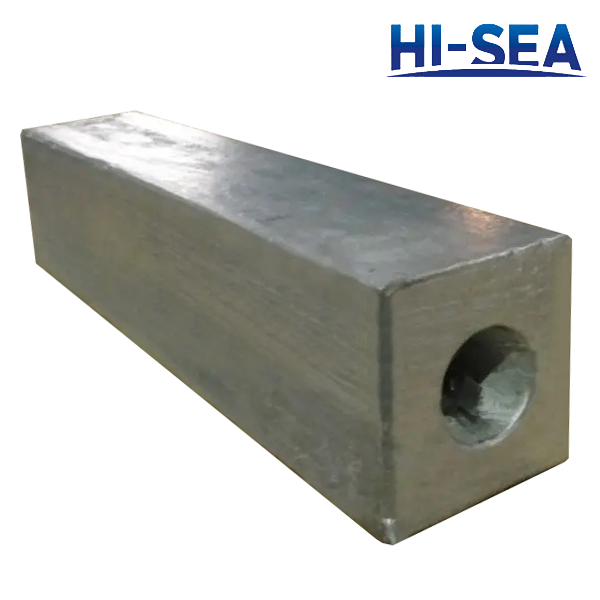

Classified by Shapes: Plates, Rods, Extruded Ribbon, Blocks

Classified by Main Material:

1.Magnesium Alloy Sacrificial Anode

Magnesium alloy sacrificial anode is suitable for the anti-corrosion protection of oil, gas, water supply and drainage pipelines in underground fresh water, underground cables, chemical industry, communication, harbor, ship, reservoir and other projects.

Chemical Composition

|

Grade |

Alloying Elements |

Impurity Elements (no greater than) |

|||||||

|

Al |

Zn |

Mn |

Mg |

Fe |

Cu |

Ni |

Si |

Ca |

|

|

MGAZ63B |

5.3-6.7 |

2.5-3.5 |

0.15-0.60 |

margin |

0.003 |

0.01 |

0.001 |

0.08 |

- |

|

MGAZ31B |

2.5-3.5 |

0.60-1.4 |

0.20-1.0 |

margin |

0.003 |

0.01 |

0.001 |

0.08 |

0.04 |

|

MGM1C |

¡Ü0.01 |

- |

0.50-1.3 |

margin |

0.01 |

0.01 |

0.001 |

0.05 |

- |

|

MG |

¡Ü0.02 |

¡Ü0.03 |

¡Ü0.01 |

¡Ý99.9% |

0.005 |

0.004 |

0.001 |

0.01 |

- |

Electrochemical Performance

|

Grade |

Open Circuit Potential |

Closed Circuit Potential |

Actual Capacitance |

Current Efficiency |

|

-V,Cu/CuSO4 |

-V,Cu/CuSO4 |

-(A*h/kg) |

% |

|

|

MGAZ63B |

1.57-1.67 |

1.52-1.57 |

¡Ý1210 |

¡Ý55 |

|

MGAZ31B |

1.57-1.67 |

1.47-1.57 |

¡Ý1210 |

¡Ý55 |

|

MGM1C |

1.77-1.82 |

1.64-1.69 |

¡Ý1100 |

¡Ý50 |

Standard Specification for Magnesium Anode

|

Size |

Specification |

Weight (kg) |

|

Length*(upper bottom+lower bottom)*Height |

||

|

MG-22 |

700¡Á(130+150)¡Á125 |

22.00 |

|

MG-14 |

700¡Á(120+100)¡Á102 |

14.00 |

|

MG-11 |

700¡Á(110+90)¡Á88 |

11.00 |

|

MG-8 |

700¡Á(95+75)¡Á75 |

8.00 |

|

MG-4 |

350¡Á(95+75)¡Á75 |

4.00 |

|

MG-2 |

350¡Á(55+60)¡Á55 |

2.00 |

|

Note: size can also be produced according to customer¡¯s requirements |

||

2.Aluminum Alloy Sacrificial Anode

Aluminum-Zinc-Indium alloy sacrificial anode is suitable for the metal cathodic protection of ships, mechanical equipment, ballast water tank, tank inner wall, coastal facilities, submarine pipeline, wharf steel pile, offshore platform and others in seawater medium.

Chemical Composition

|

Alloy Type |

Zn |

In |

Cd |

Sn |

Mg |

Si |

Ti |

Impurity, ¡Ü |

Al |

||

|

Si |

Fe |

Cu |

|||||||||

|

Al-Zn-In-Sd |

2.5-4.5 |

0.018-0.050 |

0.005-0.020 |

- |

- |

- |

- |

0.10 |

0.15 |

0.01 |

margin |

|

Al-Zn-In-Sn |

2.2-5.2 |

0.020-0.045 |

- |

0.018-0.035 |

- |

- |

- |

0.10 |

0.15 |

0.01 |

margin |

|

Al-Zn-In-Si |

5.7-7.0 |

0.025-0.035 |

- |

- |

- |

0.10-0.15 |

- |

0.10 |

0.0-15 |

0.01 |

margin |

|

Al-Zn-In-Sn-Mg |

2.5-4.0 |

0.020-0.050 |

- |

0.025-0.075 |

0.50-1.00 |

- |

- |

0.10 |

0.15 |

0.01 |

margin |

|

Al-Zn-In-Mg-Ti |

4.0-7.0 |

0.020-0.050 |

- |

- |

0.50-1.50 |

- |

0.01-0.08 |

0.10 |

0.15 |

0.01 |

margin |

Electrochemical Properities

|

Type/Index/Performance |

Open Circuit Potential-V(SCE) |

Working Potential-V(SCE) |

Actual Capacitance(A.h/kg) |

Current Efficiency% |

Dissolution Status |

|

Ordinary Aluminum Alloy Sacrificial Anode |

1.10-1.18 |

1.05-1.12 |

¡Ý2400 |

¡Ý85 |

Corrosion products are easy to fall off, the surface dissolution is even |

|

High Efficiency Aluminum Alloy Sacrificial Anode |

1.10-1.18 |

1.05-1.15-2 |

¡Ý2600 |

¡Ý90 |

|

|

Highly Activated Aluminum Alloy Sacrificial Anode |

1.45-1.50 |

1.40-1.45 |

¡Ý2080 |

¡Ý70 |

3.Zinc Alloy Sacrificial Anode

Zinc-Aluminum-Cadmium Sacrificial anodes are suitable for the cathodic protection of ships, mechanical equipment, offshore engineering and harbor facilities in fresh water or seawater medium and the pipelines and cables in low resistivity soils.

Chemical Composition (%)

|

Chemical Element |

Al |

Cd |

Impurity Element |

Zn |

|||

|

Fe |

Cu |

Pb |

Si |

||||

|

Content |

0.3~0.6 |

0.05~0.12 |

¡Ü0.005 |

¡Ü0.005 |

¡Ü0.006 |

¡Ü0.125 |

margin |

Electrochemical Properties

|

Electrochemical Properties |

Open Circuit Potential V |

Working Potential V |

Actual Capacitance (Ah/kg) |

Consumption Rate (Ah/kg) |

Current Efficiency % |

Dissolution Performance |

|

In Sea Water (1mA/cm2) |

-1.09~-1.05 |

-1.05~-1.08 |

¡Ý780 |

¡Ü11.23 |

¡Ý95 |

Surface dissolution is even, while the corrosion products are easy to fall off |

|

In Soil (0.03mA/cm2) |

¡Ü-1.05 |

¡Ü-1.03 |

¡Ý530 |

¡Ü17.25 |

¡Ý65 |

Electrochemical Properities

|

Type/Index/Performance |

Open Circuit Potential-V(SCE) |

Working Potential-V(SCE) |

Actual Capacitance(A.h/kg) |

Current Efficiency% |

Dissolution Status |

|

Ordinary Aluminum Alloy Sacrificial Anode |

1.10-1.18 |

1.05-1.12 |

¡Ý2400 |

¡Ý85 |

Corrosion products are easy to fall off, the surface dissolution is even |

|

High Efficiency Aluminum Alloy Sacrificial Anode |

1.10-1.18 |

1.05-1.15-2 |

¡Ý2600 |

¡Ý90 |

|

|

Highly Activated Aluminum Alloy Sacrificial Anode |

1.45-1.50 |

1.40-1.45 |

¡Ý2080 |

¡Ý70 |

4.Impressed Current High Silicon Cast Iron Anode

High silicon cast iron anodes are widely used for cathodic protection of external electric current in offshore oil drilling platforms, underground pipelines, and the underground cable facilities.

Chemical Composition

|

Product Name |

Chemical Element (%) |

Impurity Content (%) |

|||||

|

Si |

Cr |

Mn |

C |

Fe |

P |

S |

|

|

High Silicon Cast Iron |

14~16 |

- |

0.6~0.8 |

0.8~1.05 |

margin |

¡Ü0.25 |

¡Ü0.1 |

|

Ferrochrome Silicon |

14~16 |

4.0~4.5 |

0.6~0.8 |

0.8~1.05 |

margin |

¡Ü0.25 |

¡Ü0.1 |

Electrochemical Performance

|

Product Name |

Use Environment |

Working Current Density (A/m2) |

Consumption Rate (kg/A.a) |

|

High Silicon Cast Iron |

In seawater |

50 |

0.3~1.0 |

|

Ferrochrome Silicon |

In fresh water/soil |

10 |

0.05~0.2 |

Specifications and Sizes

|

Number |

Specification mm |

Weight kg |

Anode Cable |

|

|

Section mm2 |

Length mm |

|||

|

1 |

¦µ50¡Á1500 |

22 |

25 |

1000 |

|

2 |

¦µ75¡Á1200 |

40 |

25 |

1000 |

|

3 |

¦µ75¡Á1500 |

50 |

25 |

1000 |

|

4 |

¦µ100¡Á1500 |

90 |

25 |

1000 |

Electrochemical Properties

|

Performance /Type /Indicator |

Open circuit potential |

Working potential |

Actual capacity A¡¤h/kg |

Current efficiency |

Dissolution condition |

|

Ordinary aluminum alloy anode |

1.10-1.18 |

1.05-1.12 |

¡Ý2400 |

¡Ý85 |

Corrosion products are easy to fall off and the surface dissolves evenly. |

|

High efficiency aluminum alloy anode |

1.10-1.18 |

1.05-1.12 |

¡Ý2600 |

¡Ý90 |

|

|

Highly activated aluminum alloy anode |

1.45-1.50 |

1.40-1.45 |

¡Ý2080 |

¡Ý70 |

High Silicon Cast Iron Anode

Magnesium Alloy Sacrificial Anode for Cathodic Protection

Zinc Alloy Sacrificial Anode for Cathodic Protection

Aluminum Alloy Sacrificial Anode for Cathodic Protection