Magnesium Alloy Sacrificial Anode

[Search Related Products]

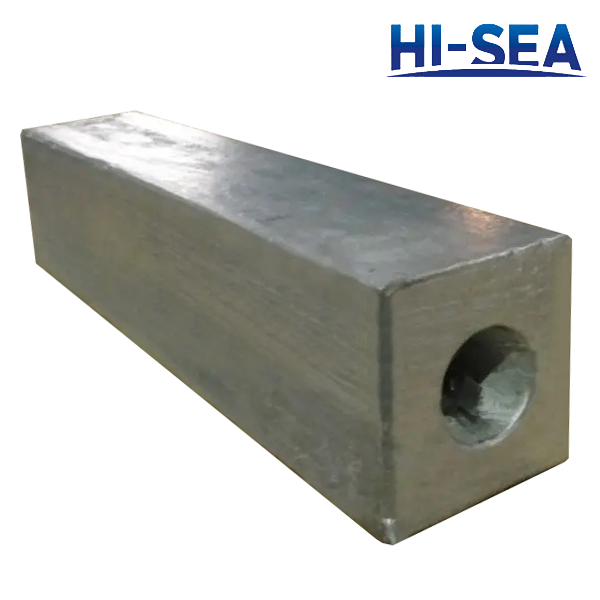

Magnesium Alloy Sacrificial Anode

Our company produces magnesium alloy sacrificial anode by using high quality raw materials, mature production technology and advanced equipment inspection, to ensure that every anode is in line with national standards.

1. Small proportion, with a high chemical activity;

2. The potential is negative and the driving potential is large;

3. Large theoretical capacity and low polarization;

4. Especially suitable for high resistivity medium

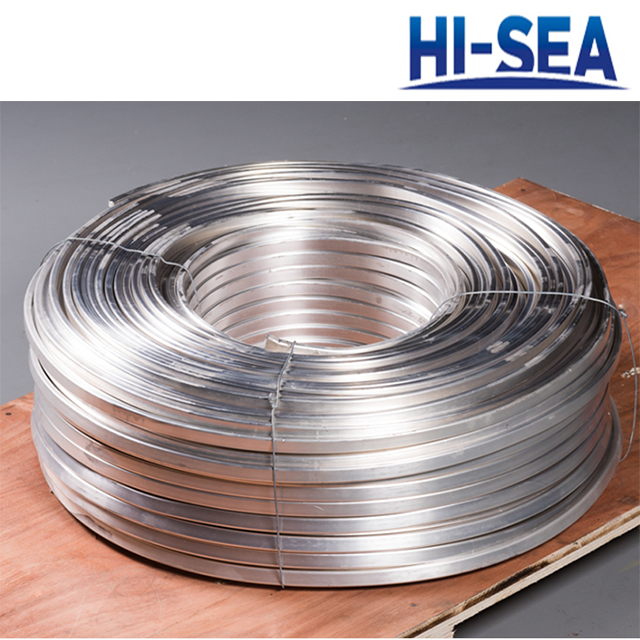

(If the resistivity is greater than 100¶ł•m, the ribbon magnesium anode is proposed)

Implementing Standards

GB/T 17731-2009 °įMagnesium Alloy Sacrificial Anode°Ī

GB/T 21488-2008 °įTechnical Specification for Cathodic Protection of Buried Steel Pipeline°Ī

Scope of Application

Applicable to anti-corrosion protection of the oil, gas, water supply and drainage pipelines in soil medium, as well as the protection of harbor, ship, reservoir gate and other projects in water.

Matters Need Attention in Use

1. Avoiding the collision with the steel structure;

2. Should be buried in the low-lying and damp places; the anode must be packed in filling bag before being buried in soil;

3. After being placed in the ground, the filling bag with anodes should be soaked with water before being covered by soil.

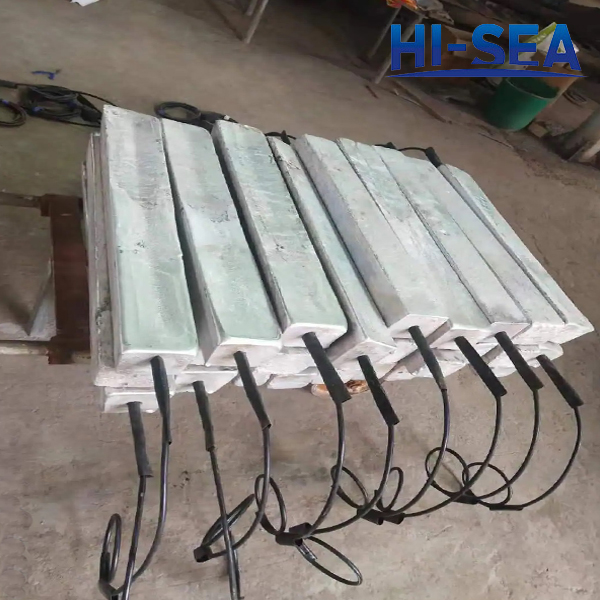

Package Assembly of Magnesium Alloy Sacrificial Anode

Sacrificial anode package assembly is designed to adapt to the requirements of the construction of high rhythm and high efficiency of construction. It is based on the previous single sacrificial anode and supplemented with package assembly to make customer°Įs construction more convenient, time-saving and labor-saving.

Assembly Configuration

Any specifications of sacrificial anode, a single cable, several kilograms of filling materials, a cotton bag, a plastic woven bag.

The Composition of Filling Material

1. Gypsum Powder: 75%; 2. Bentonite: 20%; 3. Anhydrous Sodium Sulfate:5%

Chemical Composition

|

Grade |

Alloying Elements |

Impurity Elements (no greater than) |

|||||||

|

Al |

Zn |

Mn |

Mg |

Fe |

Cu |

Ni |

Si |

Ca |

|

|

MGAZ63B |

5.3-6.7 |

2.5-3.5 |

0.15-0.60 |

margin |

0.003 |

0.01 |

0.001 |

0.08 |

- |

|

MGAZ31B |

2.5-3.5 |

0.60-1.4 |

0.20-1.0 |

margin |

0.003 |

0.01 |

0.001 |

0.08 |

0.04 |

|

MGM1C |

°‹0.01 |

- |

0.50-1.3 |

margin |

0.01 |

0.01 |

0.001 |

0.05 |

- |

|

MG |

°‹0.02 |

°‹0.03 |

°‹0.01 |

°›99.9% |

0.005 |

0.004 |

0.001 |

0.01 |

- |

Electrochemical Performance

|

Grade |

Open Circuit Potential |

Closed Circuit Potential |

Actual Capacitance |

Current Efficiency |

|

-V,Cu/CuSO4 |

-V,Cu/CuSO4 |

-(A*h/kg) |

% |

|

|

MGAZ63B |

1.57-1.67 |

1.52-1.57 |

°›1210 |

°›55 |

|

MGAZ31B |

1.57-1.67 |

1.47-1.57 |

°›1210 |

°›55 |

|

MGM1C |

1.77-1.82 |

1.64-1.69 |

°›1100 |

°›50 |

Standard Specification for Magnesium Anode

|

Size |

Specification |

Weight (kg) |

|

Length*(upper bottom+lower bottom)*Height |

||

|

MG-22 |

700°Ń(130+150)°Ń125 |

22.00 |

|

MG-14 |

700°Ń(120+100)°Ń102 |

14.00 |

|

MG-11 |

700°Ń(110+90)°Ń88 |

11.00 |

|

MG-8 |

700°Ń(95+75)°Ń75 |

8.00 |

|

MG-4 |

350°Ń(95+75)°Ń75 |

4.00 |

|

MG-2 |

350°Ń(55+60)°Ń55 |

2.00 |

|

Note: size can also be produced according to customer°Įs requirements |

||

Magnesium Alloy Sacrificial Anode for Cathodic Protection