Marine Prefabricated Wet Unit

[Search Related Products]

Marine Prefabricated Wet Unit

Hi-sea marine prefabricated wet unit is composed of wall panel,ceiling panel,bottom plate,hardware,sanitary ware,lighting and water and electricity system.It is an independent and multi-function unit which has the functions of washing the face,showering and WC in a limited space.

As the decorative materials for the ships,our overall wet unit is widely used in various cabins in the letter,such as luxury cruise ships,maritime hotel,ferries,oil platforms,cargo ships,etc.It also can be used for land-based hotels,apartments and container mobile homes,etc.High-grade design,fabrication and installation bring economical and comfortable bath health space.Its design completely conforms to the ISO standard, IMO standard, and the requirements of various Classification Societies,such as CCS,LR,GL,ABS,KR,DNV,NK,EC,etc.

Characteristics of marine prefabricated overall wet unit:

Personalized overall design,factory production

Excellent structure,flexible configuration,environmental protection and safety,thermal insulation,easy to clean

Efficient installation,shorten the construction cycle

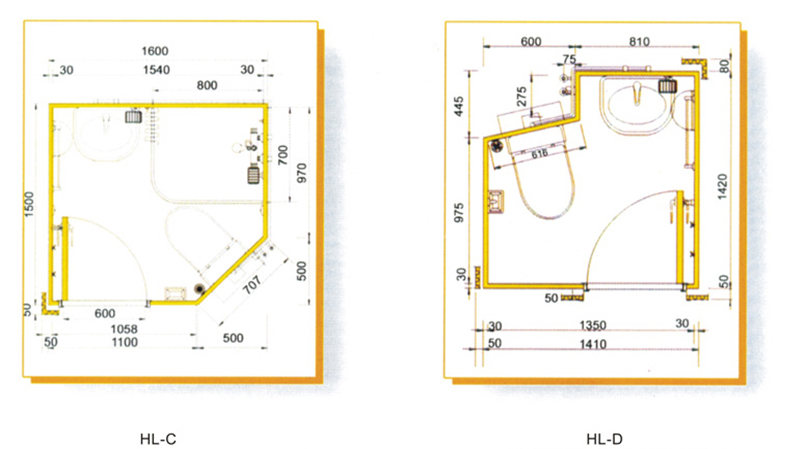

Material are various,such as steel plate,stainless steel ,aluminum,GRP,mosaic floor,epoxy floor,PVC,ceramic tile floor,etc.

Note:The size of Hi-sea marine prefabricated wet unit can be customized according to clientsĄŻ special requirements.For any more information,please feel free to contact us directly.

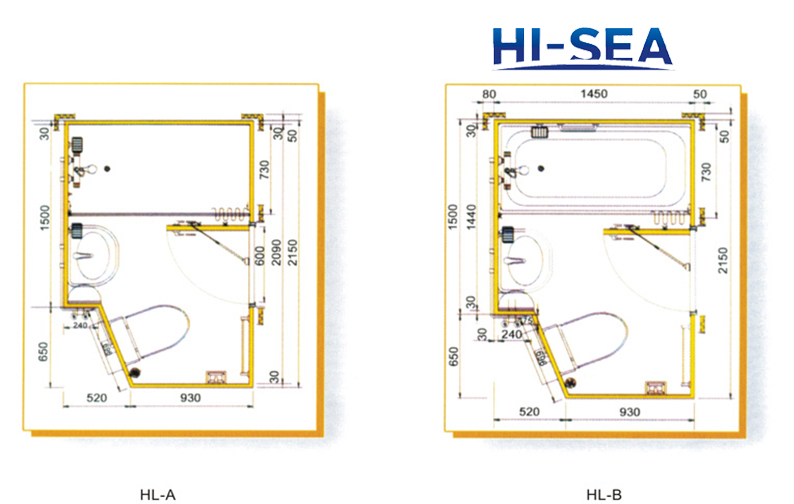

Ichnography of Marine Prefabricated Wet Unit

Examples of Standard Types

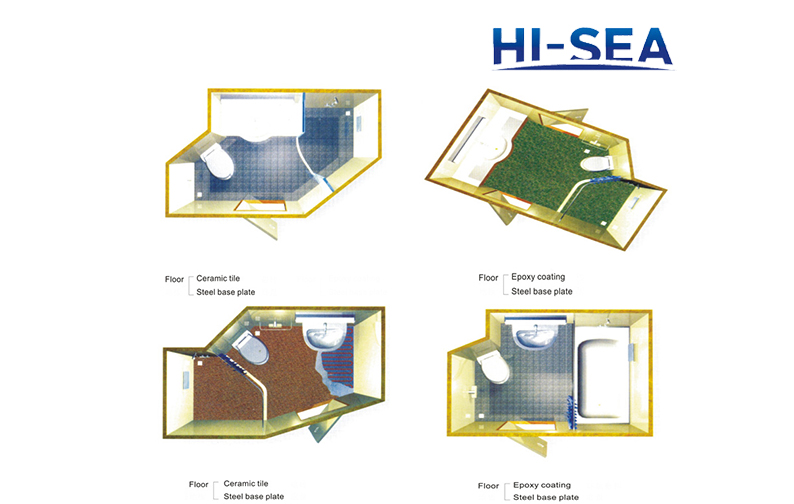

Structure of Base Plate:

Stainless steel separate shower area from others,floor pan with slope.

Shower area is lower,floor pan with slope.

Structure of Base Plate

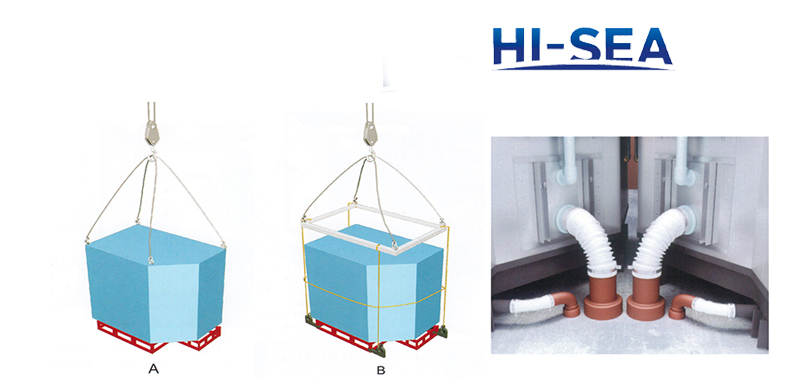

Hoisting Diagram:

The hoisting method is easy & safe.To use the hook with steel wire to hitch the four rings at the bathroom unit evenly & slowly.

To low down the bathroom unit evenly & slowly at the installation position.

The A,B hoisting methods can be used according to different types of base plate.

Position & Installation:

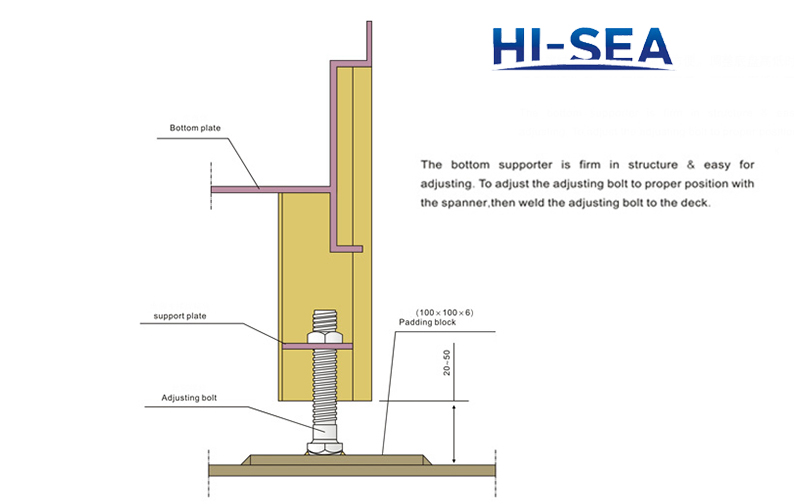

Unit in place,the ground screw control into the foot support,adjust the individual screws,so that the unit completely smooth contact with the deck,and finally to the ground screw,and the deck welding firm.

The whole ship piping system pressure before the pressure test,make sure the unit water inlet valve closed,to avoid instantaneous pressure too much damage to the unit piping systems and sophisticated bathroom accessories;

Health unit piping test pressure range:0.6~0.8Mpa

Hoisting and Instanllation

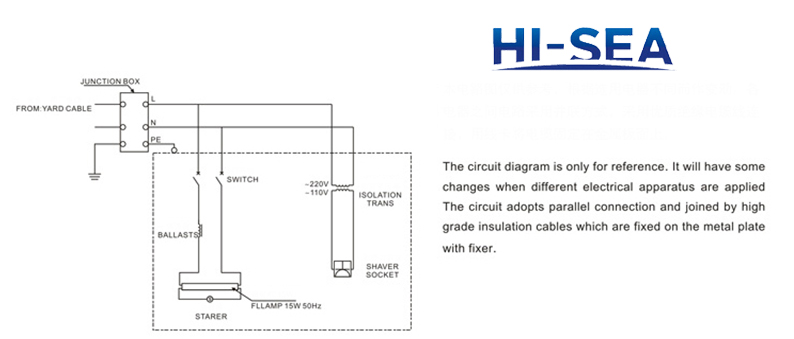

Circuit Diagram

Bottom Support

Picture of Marine Prefabricated Wet Unit

Pictures of Marine Sanitaryware and Hardware are as follows:

Marine Sanitaryware and Hardware(1)

Marine Sanitaryware and Hardware(2)

Certificates: