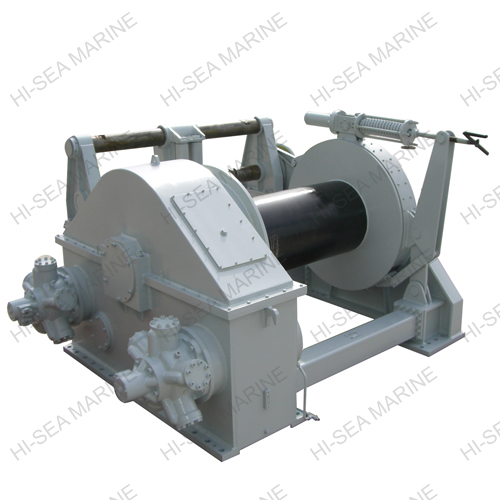

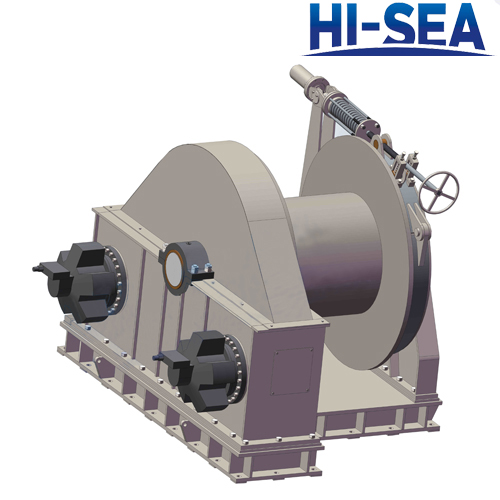

Marine Winch

[Search Related Products]

Have a rugged design, heavy duty split bronze bearings and amply dimensioned brakes. The operating mechanisms for brakes and cluthes are desgined for easy and safe manual operation, but may also be remotely operated by hydraulic cylinders. The brakes are easily adjustable, and all transferred of external forces to the deck construction is via the foundation bolts. No special welded steel constructions, more flexible for variations winch may occur. This arrangement also has the benefit of making transportation of the winches simpler and less expensive. The manual cluth operating is with spindles for winches for winches from 16 tonnes pulling power and upwards. The winch design provides easy access to all points for lubrication and inspection. Gear may be delivered as open type with steel protection cover, or as totally enclosed gears with oil bath. Mooring Winch can be designed for operating under very low temperature conditions, which also requires special quality steel materials, with high ductility. HP(high pressure) winches are for 250bar, remote control, self tension etc. As required for the individual installation.

Offshore Towing Winch:

1. For all types of tugs and offshore vessels,also combined with cable lifters. Product range from 5-150 tons.

2. Towing drum, declutchable and with band brake.

3. Automatic/mechanical spooling device

4. Friction cluth and spindle band brake are hydraulically remotely controlled, manual operation of the spindle band brake also possible at the winch. The friction cluth assures that in every possible towing situation the drum can be disengaged without endangering the operative driving components.

5. Warping head fixed on the intermediate shaft.

6. Certificate, CCS, ABS, GL, BV, NK, LR, DNV, RS, KR, etc

Hydrauic Type:

|

Rated Pull(kN) |

Rated Speed(m/min) |

Drum Capacity(m) |

Motor Power(kW) |

|

10 |

¡Ý12 |

§¶10§ç150 |

5.5 |

|

20 |

¡Ý12 |

§¶15§ç150 |

11 |

|

30 |

¡Ý15 |

§¶17§ç150 |

15 |

|

40 |

¡Ý15 |

§¶18§ç150 |

22 |

|

50 |

¡Ý15 |

§¶20.5§ç150 |

30 |

|

75 |

¡Ý15 |

§¶26§ç200 |

45 |

|

80 |

¡Ý15 |

§¶26§ç200 |

45 |

|

100 |

¡Ý15 |

§¶30§ç200 |

45 |

|

125 |

¡Ý15 |

§¶30§ç200 |

75 |

|

160 |

¡Ý15 |

§¶32§ç250 |

75 |

|

200 |

¡Ý9.6 |

§¶41§ç250 |

75 |

|

250 |

¡Ý9.6 |

§¶44.5§ç250 |

90 |

|

315 |

¡Ý7.8 |

§¶52§ç250 |

90 |

|

400 |

¡Ý7.8 |

§¶56§ç250 |

110 |

|

450 |

¡Ý7.8 |

§¶56§ç250 |

110 |

|

500 |

¡Ý7.8 |

§¶58§ç250 |

110 |

|

560 |

¡Ý6 |

§¶64§ç250 |

132 |

|

600 |

¡Ý6 |

§¶64§ç250 |

132 |

|

650 |

¡Ý6 |

§¶70§ç250 |

132 |

|

1000 |

¡Ý4 |

§¶85§ç250 |

132 |

|

1200 |

¡Ý4 |

§¶95§ç250 |

160 |

|

1500 |

¡Ý4 |

§¶95§ç250 |

200 |

|

1800 |

¡Ý4 |

§¶95§ç250 |

250 |

|

2000 |

¡Ý4 |

§¶100§ç250 |

270 |

Electric Type:

|

Rated Pull(kN) |

Rated Speed(m/min) |

Drum Capacity(m) |

Motor Power(kW) |

|

5 |

¡Ý12 |

§¶8§ç100 |

3/1.2 |

|

10 |

¡Ý12 |

§¶10§ç150 |

4.3/1.7 |

|

20 |

¡Ý12 |

§¶15§ç150 |

8.5/3.5 |

|

30 |

¡Ý15 |

§¶17§ç150 |

11/11/7.5 |

|

40 |

¡Ý15 |

§¶18§ç150 |

16/16/11 |

|

50 |

¡Ý15 |

§¶20.5§ç150 |

22/22/16 |

|

75 |

¡Ý15 |

§¶26§ç200 |

30/30/22 |

|

80 |

¡Ý15 |

§¶26§ç200 |

30/30/22 |

|

100 |

¡Ý15 |

§¶30§ç200 |

45/45/30 |

|

125 |

¡Ý15 |

§¶30§ç200 |

45/45/30 |

|

160 |

¡Ý15 |

§¶32§ç250 |

60/60/45 |

|

200 |

¡Ý9.6 |

§¶41§ç250 |

60/60/45 |

|

250 |

¡Ý9.6 |

§¶44.5§ç250 |

60/60/45 |

|

315 |

¡Ý7.8 |

§¶52§ç250 |

60/60/45 |

|

400 |

¡Ý7.8 |

§¶56§ç250 |

85/85/64 |

|

450 |

¡Ý7.8 |

§¶56§ç250 |

85/85/64 |

|

500 |

¡Ý7.8 |

§¶58§ç250 |

85/85/64 |

|

560 |

¡Ý6 |

§¶64§ç250 |

85/85/64 |

|

600 |

¡Ý6 |

§¶64§ç250 |

85/85/64 |

|

650 |

¡Ý6 |

§¶70§ç250 |

85/85/64 |

|

1000 |

¡Ý4 |

§¶85§ç250 |

85/85/64 |

|

1200 |

¡Ý4 |

§¶95§ç250 |

120/120/90 |

|

1500 |

¡Ý4 |

§¶95§ç250 |

150/150/72 |

|

1800 |

¡Ý4 |

§¶95§ç250 |

150/150/72 |

|

2000 |

¡Ý4 |

§¶100§ç250 |

180/180/135 |