Marine Cast Iron Flanged Stop valve GB/T590-1993

[Search Related Products]

Marine Cast Iron Flanged Stop valve GB/T590-1993:

1.Design standard:GB/T11689.

2.End standard:GB/T2501&GB/T569.

3.End type:Flange.

4.PN:0.6/1.0/1.6Mpa.

5.DN:20mm-300mm.

6.Main material:

- Body/Bonnet:HT200;

- Seat:SS410/BC;

- Stem:SS410/BS;

- Disc:SS410/BC.

7.Application:Sea water piping,fresh water piping,oil piping and steam piping.

8.Function:Such valves are used for on-off duty and regulating the flow rate.

9.Fundamental dimensions for Marine Cast Iron Flanged Stop valve GB/T590-1993:

Chart1 Fundamental dimensions of type A and B:

|

PN |

DN |

Construction dimensions |

|

|

|

|

|

|

|||||||||||

|

|

|

H1 |

Thickness |

|

|

|

Lift |

Weight(kg) |

|||||||||||

|

(MPa) |

(mm) |

A |

B |

A |

B |

B |

6 |

D |

D1 |

D2 |

do |

b |

n |

Th |

Do |

S |

m |

A |

B |

|

1.0 |

65 |

290 |

115 |

310 |

277 |

1 15 |

9 |

155 |

123 |

104 |

15 |

15 |

6 |

M14 |

140 |

12 |

18 |

18 9 |

16 7 |

|

80 |

310 |

125 |

345 |

304 |

125 |

9 |

170 |

138 |

118 |

15 |

15 |

8 |

M14 |

160 |

14 |

24 |

23 0 |

19 9 |

|

|

100 |

350 |

150 |

374 |

325 |

135 |

10 |

190 |

158 |

138 |

15 |

15 |

8 |

M14 |

180 |

14 |

35 |

31 0 |

27 2 |

|

|

125 |

400 |

175 |

426 |

366 |

155 |

10 |

215 |

183 |

164 |

15 |

15 |

10 |

M14 |

200 |

17 |

44 |

39 3 |

37 5 |

|

|

150 |

480 |

180 |

482 |

410 |

160 |

11 |

240 |

208 |

190 |

15 |

16 |

12 |

M14 |

200 |

17 |

57 |

55 5 |

48 4 |

|

|

1.6 |

20 |

150 |

75 |

217 |

203 |

75 |

7 |

95 |

68 |

48 |

13 |

14 |

4 |

M12 |

80 |

8 |

7 |

5 7 |

5 1 |

|

25 |

160 |

80 |

217 |

203 |

80 |

7 |

105 |

73 |

56 |

13 |

14 |

4 |

M12 |

80 |

8 |

7 |

6 0 |

5 6 |

|

|

32 |

180 |

85 |

236 |

216 |

85 |

7 |

1 15 |

83 |

64 |

15 |

15 |

6 |

M14 |

100 |

9 |

9 |

7 0 |

6 9 |

|

|

40 |

200 |

90 |

260 |

236 |

90 |

8 |

125 |

93 |

74 |

15 |

16 |

6 |

M14 |

120 |

1 1 |

11 |

9 2 |

8 5 |

|

|

50 |

230 |

95 |

288 |

258 |

95 |

8 |

135 |

103 |

84 |

15 |

16 |

6 |

M14 |

140 |

12 |

14 |

11 9 |

11 3 |

|

Chart2 Fundamental dimensions of type AS and BS:

|

PN |

DN |

Construction dimensions |

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

Lift |

Weight(kg) |

|||||||||||

|

(MPa) |

(mm) |

AS |

BS |

AS |

BS |

BS |

6 |

D |

D1 |

D2 |

do |

b |

n |

Th |

Do |

S |

m |

AS |

BS |

|

0.6 |

50 |

230 |

125 |

288 |

258 |

125 |

8 |

140 |

1 10 |

90 |

14 |

16 |

4 |

M12 |

140 |

12 |

14 |

12 2 |

12 2 |

|

65 |

290 |

145 |

310 |

277 |

145 |

9 |

160 |

130 |

1 10 |

14 |

16 |

4 |

M12 |

140 |

12 |

18 |

19 2 |

17 7 |

|

|

80 |

310 |

155 |

345 |

304 |

155 |

9 |

190 |

150 |

128 |

18 |

18 |

4 |

M16 |

160 |

14 |

24 |

23 8 |

21 7 |

|

|

100 |

350 |

175 |

374 |

325 |

175 |

10 |

210 |

170 |

148 |

18 |

18 |

4 |

M16 |

180 |

14 |

35 |

34 5 |

32 3 |

|

|

125 |

400 |

200 |

426 |

366 |

200 |

10 |

240 |

200 |

178 |

18 |

20 |

8 |

M16 |

200 |

17 |

44 |

42 5 |

42 8 |

|

|

150 |

480 |

225 |

482 |

410 |

225 |

11 |

265 |

225 |

202 |

18 |

20 |

8 |

M16 |

200 |

17 |

57 |

58 7 |

55 8 |

|

|

175 |

540 |

225 |

557 |

489 |

225 |

11 |

295 |

255 |

232 |

18 |

22 |

8 |

M16 |

200 |

17 |

60 |

76 8 |

70 3 |

|

|

200 |

600 |

275 |

621 |

549 |

275 |

11 |

320 |

280 |

258 |

18 |

22 |

8 |

M16 |

280 |

24 |

68 |

102 0 |

95 6 |

|

|

250 |

730 |

325 |

721 |

623 |

325 |

13 |

375 |

335 |

312 |

18 |

24 |

12 |

M16 |

360 |

27 |

80 |

158 0 |

151 0 |

|

|

300 |

850 |

375 |

794 |

691 |

375 |

13 |

440 |

395 |

365 |

22 |

24 |

12 |

M20 |

450 |

32 |

100 |

218 0 |

207 0 |

|

|

1.0 |

65 |

290 |

145 |

310 |

277 |

145 |

9 |

185 |

145 |

122 |

18 |

20 |

4 |

M16 |

140 |

12 |

18 |

21 6 |

20 1 |

|

80 |

310 |

155 |

345 |

304 |

155 |

9 |

200 |

160 |

133 |

18 |

22 |

8 |

M16 |

160 |

14 |

24 |

26 0 |

23 9 |

|

|

100 |

350 |

175 |

374 |

325 |

175 |

10 |

220 |

180 |

158 |

18 |

24 |

8 |

M16 |

180 |

14 |

35 |

35 0 |

32 8 |

|

|

125 |

400 |

200 |

426 |

366 |

200 |

10 |

250 |

210 |

184 |

18 |

26 |

8 |

M16 |

200 |

17 |

44 |

44 3 |

44 6 |

|

|

150 |

480 |

225 |

482 |

410 |

225 |

11 |

285 |

240 |

212 |

22 |

26 |

8 |

M20 |

200 |

17 |

57 |

62 7 |

59 8 |

|

|

175 |

540 |

225 |

557 |

489 |

225 |

11 |

315 |

270 |

242 |

22 |

28 |

8 |

M20 |

280 |

24 |

60 |

80 3 |

73 8 |

|

|

200 |

600 |

275 |

621 |

543 |

275 |

11 |

340 |

295 |

268 |

22 |

28 |

8 |

M20 |

360 |

27 |

68 |

106 0 |

99 6 |

|

|

250 |

730 |

325 |

721 |

623 |

325 |

13 |

395 |

350 |

320 |

22 |

28 |

12 |

M20 |

450 |

32 |

80 |

160 0 |

153 0 |

|

|

1.6 |

20 |

150 |

95 |

217 |

203 |

95 |

7 |

105 |

75 |

58 |

14 |

16 |

4 |

M12 |

80 |

8 |

7 |

6 2 |

5 7 |

|

25 |

160 |

100 |

217 |

203 |

100 |

7 |

1 15 |

85 |

68 |

14 |

16 |

4 |

M12 |

80 |

8 |

7 |

6 6 |

6 4 |

|

|

32 |

180 |

105 |

236 |

216 |

105 |

7 |

140 |

100 |

78 |

18 |

18 |

4 |

M16 |

100 |

9 |

9 |

8 6 |

8 7 |

|

|

40 |

200 |

115 |

260 |

236 |

1 15 |

8 |

150 |

1 10 |

88 |

18 |

18 |

4 |

M16 |

120 |

1 1 |

1 1 |

11 0 |

10 7 |

|

|

50 |

230 |

125 |

288 |

258 |

125 |

8 |

165 |

125 |

102 |

18 |

20 |

4 |

M16 |

140 |

12 |

14 |

14 2 |

14 2 |

|

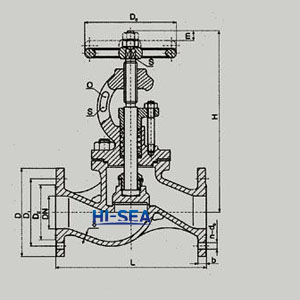

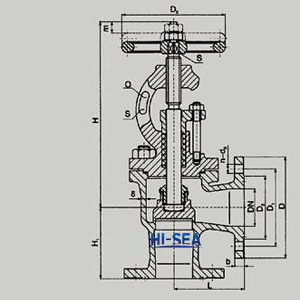

10.Drawing of Marine Cast Iron Flanged Stop valve GB/T590-1993:

Type A/AS:

Type B/BS:

11.Marine Cast Iron Flanged Stop valve GB/T590-1993 factory: