Dredge Floater

[Search Related Products]

Description of Dredge Floater

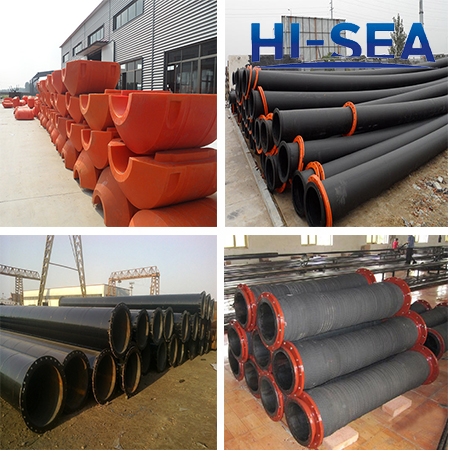

Dredge Floater is made from polyethylene and polyurethane closed-cell foam.Dredge floater can be used for dredge steel pipe and dredge HDPE pipe.It is available for providing buoyancy for dredge pipeline.Hi-sea dredge floater can be produced according to the specific design of dredging ship and the construction conditions of production.

Polyethylene floater is currently popular floating material of dredger pipeline.It has various features,such as small volume,light weight,big buoyancy,wind resistance,aging resistance,long service life,etc.We mainly use medium density polyethylene material and high density polyethylene material.The hull of medium density polyethylene floater with excellent flexibility is filled with polyurethane foam.Its surface is smooth and wear-resisting.

Hi-sea Dredge Floater includes Dredge PE Floater and Dredge MDPE Floater.More designs can be customized according to clients' specific requirements.For any more information,please feel free to contact us directly.

Features of Dredge Floater

Our dredge pipe floater has compact and reasonable structure,easy installation and excellent performance.

It is good toughness and strong environmental stress cracking resistance.It is suitable for offshore and river and lake construction.

It is light weight and high resistance to wear,so it is good for installation and transportation.The cost is low.

It is flexible.The maintenance cost is low,the installation is simple. Low absorption rate.

The price is reasonable,the service is excellent.

The service temperature range is from -60°„C to 80°„C.

Application of Dredge Floater

Ensure dredge pipeline float on the surface of water.

Benefit for repairing and checking the dredge pipeline.

The colorful shell can be as anti-collision warning sign to protect dredge pipeline.

Lower the dredge project cost and maintenance cost,shorten the construction period.

Specifications:

|

Item |

Technical Index of Hull |

Item |

Inside Technical Index |

|

Tensile Strength |

°›13.1MPa |

Water Absorption |

1-2g/100cm2 |

|

Break Elongation |

°›11.1% |

Breaking Strength |

0.08-0.1MPa |

|

Impact Strength |

°›32.4KJ/m2 |

Breaking Elongation |

4-6% |

|

Bending Strength |

°›15.7MPa |

Compressive Strength |

0.1-0.24MPa |

|

Weather Resistance |

Break Elongation %°› |

10 |

|

|

After total aging energy°›3.5GJ/m2 |

Oxidative Induction Time 200°„Cmm°› |

10 |

|

|

Pipe I.D. |

Thickness of Pipe |

Float I.D. |

Float O.D. |

Float Length |

Thickness of Plastic |

Net Buoyancy |

|

mm |

mm |

mm |

mm |

mm |

mm |

KGS/Float |

|

200 |

6 |

220 |

500 |

800 |

7 |

200 |

|

285 |

6 |

300 |

700 |

1200 |

7 |

420 |

|

350 |

6 |

375 |

1100 |

1100 |

7 |

920 |

|

400 |

8 |

414 |

1100 |

1200 |

8 |

1020 |

|

414 |

8 |

430 |

1200 |

1200 |

8 |

1200 |

|

450 |

8 |

480 |

1300 |

1300 |

8 |

1500 |

|

500 |

10 |

580 |

1400 |

1500 |

9 |

2219 |

|

550 |

10 |

580 |

1400 |

1600 |

10 |

2310 |

|

600 |

10 |

630 |

1400 |

1700 |

11 |

2400 |

|

650 |

10 |

680 |

1480 |

1800 |

11.5 |

2930 |

|

700 |

12 |

730 |

1600 |

1900 |

12 |

3593 |

|

750 |

12 |

780 |

1600 |

2000 |

13 |

3800 |

|

800 |

15 |

830 |

1800 |

2000 |

14 |

4800 |

|

850 |

15 |

880 |

1800 |

2200 |

15 |

5140 |

|

900 |

18 |

940 |

2200 |

2500 |

16 |

8180 |

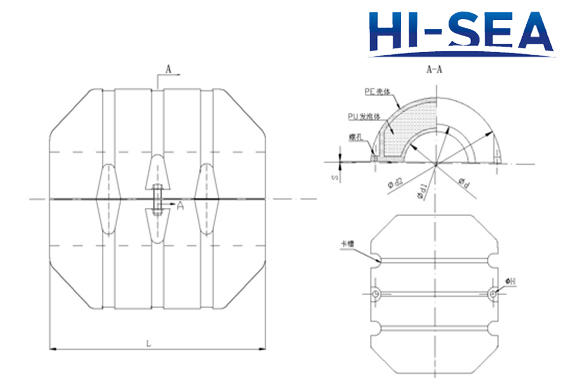

Drawing of Dredge Floater

Dredge Floater(1)

Dredge Floater (2)

Dredge Floater (3)

Dredge Floater(4)

Dredge Floater(5)

Dredge Pipe Floater