Electrohydraulic Servo Numeric-control Folding Machine

[Search Related Products]

Electrohydraulic Servo Numeric-control Folding Machine

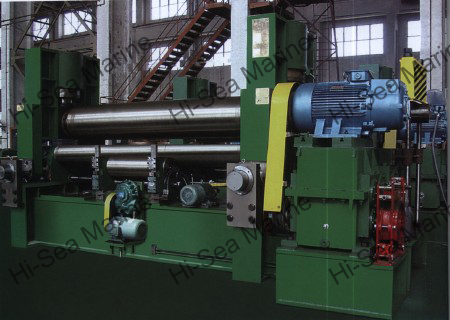

1. Overall welded and processed structure.

2. Closed loop control mode composed of electric-hydraulic servo valve and measure ruler, ensure the highest controlling precision, bending accuracy and repositioning accuracy anre alsi reach the highest level.

3. Backgauge mechanism can nontrol several backgauge axes.

4. Integrated hydraulic system decreases the pipe connections, oil leakage, and increases the stability and overall beautifies.

5. Hydraulic compensation mechanism help to prevent the deformed slider from affecting the quality of the workpiece, and the compensation mechanism is adjusted automatically by the CNC controller which is convenient and accuracy.

6. NC controller uses Holland DELEM, Italy ESA or Swiss CYBELEC with Multi-languages.

Main Parameters

| Model | Nominal Pressure (kn) | Length of Working Table (mm) | The Depth of Throat (mm) | Ram Stroke (mm) | Number of Stroke (m/min-1£© | Motor Power (kw) |

| WC67Y/K-40/2200 | 400 | 2200 | 200 | 100 | 11 | 4 |

| WC67Y/K-40/2500 | 400 | 2500 | 200 | 100 | 11 | 4 |

| WC67Y/K-50/2500 | 500 | 2500 | 200 | 100 | 11 | 5.5 |

| WC67Y/K-63/2500 | 630 | 2500 | 250 | 100 | 10 | 5.5 |

| WC67Y/K-63/3200 | 630 | 3200 | 250 | 100 | 10 | 5.5 |

| WC67Y/K-80/2500 | 800 | 2500 | 320 | 150 | 8 | 7.5 |

| WC67Y/K-80/3200 | 800 | 3200 | 320 | 150 | 8 | 7.5 |

| WC67Y/K-100/2500 | 1000 | 2500 | 320 | 150 | 8 | 7.5 |

| WC67Y/K-100/3200 | 1000 | 3200 | 320 | 150 | 8 | 7.5 |

| WC67Y/K-100/4000 | 1000 | 4000 | 400 | 150 | 8 | 7.5 |

| WC67Y/K-125/2500 | 1250 | 2500 | 320 | 150 | 8 | 7.5 |

| WC67Y/K-125/3200 | 1250 | 3200 | 320 | 150 | 8 | 7.5 |

| WC67Y/K-125/4000 | 1250 | 4000 | 400 | 150 | 8 | 7.5 |

| WC67Y/K-160/3200 | 1600 | 3200 | 400 | 180 | 8 | 11 |

| WC67Y/K-160/4000 | 1600 | 4000 | 400 | 180 | 8 | 11 |

| WC67Y/K-160/5000 | 1600 | 5000 | 400 | 180 | 7 | 11 |

| WC67Y/K-160/6000 | 1600 | 6000 | 400 | 200 | 7 | 15 |

| WC67Y/K-200/3200 | 2000 | 3200 | 400 | 200 | 7 | 15 |

| WC67Y/K-200/4000 | 2000 | 4000 | 400 | 200 | 7 | 15 |

| WC67Y/K-200/6000 | 2000 | 6000 | 400 | 200 | 7 | 15 |

| WC67Y/K-250/3200 | 2500 | 3200 | 400 | 200 | 7 | 18.5 |

| WC67Y/K-250/4000 | 2500 | 4000 | 400 | 200 | 7 | 18.5 |

| WC67Y/K-250/6000 | 2500 | 6000 | 400 | 250 | 7 | 18.5 |

| WC67Y/K-300/3200 | 3000 | 3200 | 400 | 250 | 7 | 22 |

| WC67Y/K-300/4000 | 3000 | 4000 | 400 | 250 | 7 | 22 |

| WC67Y/K-300/6000 | 3000 | 6000 | 400 | 250 | 7 | 30 |

| WC67Y/K-300/7000 | 3000 | 7000 | 400 | 250 | 7 | 30 |

| WC67Y/K-400/6000 | 4000 | 6000 | 400 | 250 | 7 | 30 |

| WC67Y/K-500/6000 | 5000 | 6000 | 400 | 300 | 7 | 37 |

| WC67Y/K-600/6000 | 6000 | 6000 | 420 | 300 | 7 | 37 |

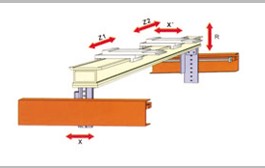

Άς(X, R) Backgauges

Άσ (X, R, Z1, Z2) Backgauges

Type Άς: 2 NC axles (X, R)

2 manual-axles (Z1, Z2)

Type Άσ: 4 NC axles (X, R, Z1, Z2)

Type Άτ: 5 NC axles (X, R, Z1, Z2, H)

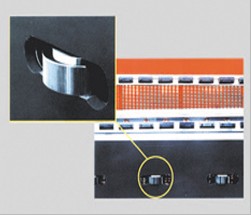

High precision grating feet installed on C type rack,

overcome the fuselage bending deformation folde

in half the influence of accuracy.

The equipment of automatic hydraulic crowning

system can compensate the bending tolerance

caused by the ram torsion.

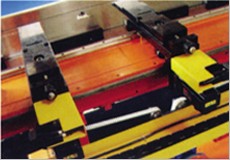

Import high quality servo system

Performances:

1. Integrity of torque control, speed control and position control.

2. High speed, high accuracy operation.

3. High frequency response and short setting time.

4. Automatic adjustment of internal gain.

5. Small volume, easy operation and easy wrie connection.

Mould exchange clamping device

Simple but stable and reliable back gauge has elegant appearance