Sand Blasting Room

[Search Related Products]

Sand Blasting Room

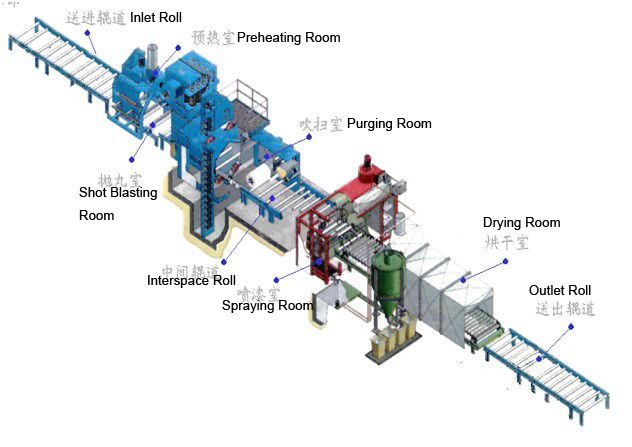

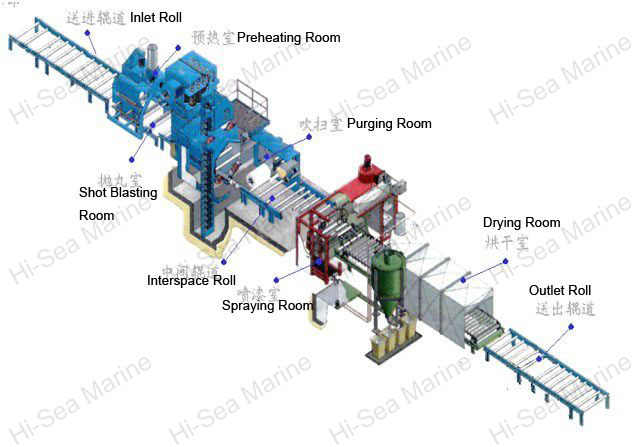

The sand blasting room is comprised of cross in-feed transverse conveying unit (option), in-feed conveying rollers, sand blasting system, dust removing system, painting system, drying system, organic gas and paint mist treatment device, out-feed conveying system cross out-feed transverse conveying unit (option) and electrical system and so on. This equipment is mainly used to do shot blasting to steel plate / profiles to get a clean surface of Sa2.5 with certain roughness. After shot blasting, the painting system will paint anti-rust coating layer on steel. This ensures no second pollution during processing.

The whole line of this production line is 58mtr.s. It is controlled by PLC electrical controller.

General Parameters

|

Name |

Unit |

Technical Data |

|

Max loading of conveying rollers |

t/m |

1.5 |

|

Delivery speed |

m/min |

0.5~5 |

|

Working speed for steel plate |

m/min |

0.5~2.5 |

|

Working speed for steel profile |

m/min |

0.5~1.5 |

|

Annual output |

t |

50000 (250 working days, 8 hours / shift) |

|

Surface quality |

|

Sa2.5 GB8923-88 |

|

Paint film Thickness |

¦Ìm |

15~25 |

|

Temperature in drying chamber |

¡æ |

40-70 |

|

Compressed air consumption |

cbm/h |

6 |

|

Mpa |

0.4~0.8 |

|

|

Dust Emission density |

mg/cbm |

80 |

|

Noise of whole equipment |

dB |

¡Ü85 |

|

Power of whole line |

kw |

About 395 |

|

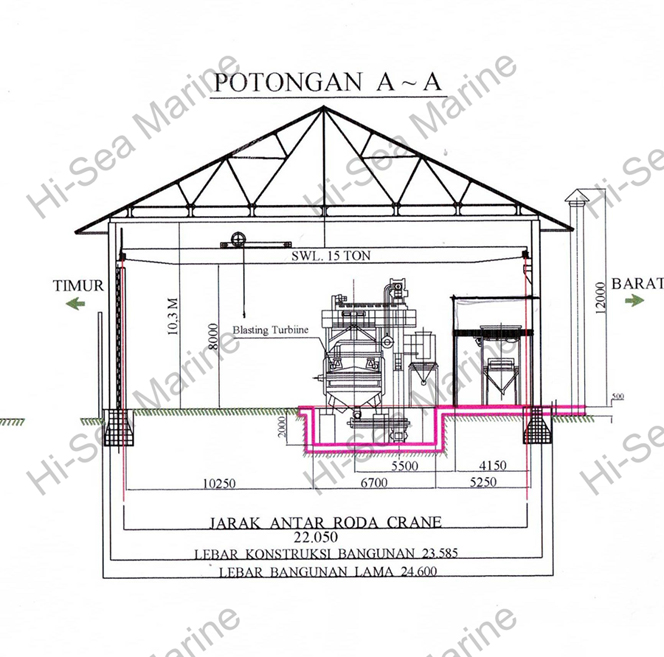

Size of whole line |

|

Refer to general drawing |

All the system: