Steel Peening House

[Search Related Products]

Steel Peening House

¡òShot blasting, painting of steel plates

¡òPreparation surface for next procedure

¡òEngineer machine, Mining machine, Chemical equipment, pressure vessel, Vehicle traffic, ship building and Building/Construction material

Uncomplicated operation, high-quality, easy maintenance and cleaning, low operating costs as well as being informed about environmental restrictions and paint developments are the keynotes for our shot blasting and painting lines.

Products, based on clear long-term technological concepts, have the technical maturity and quality to ensure maximum customer benefit!

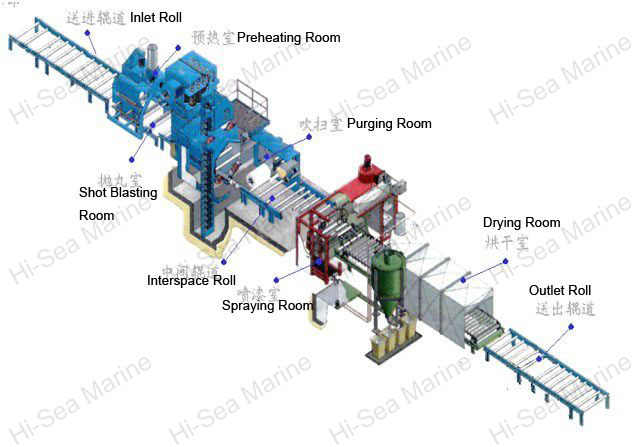

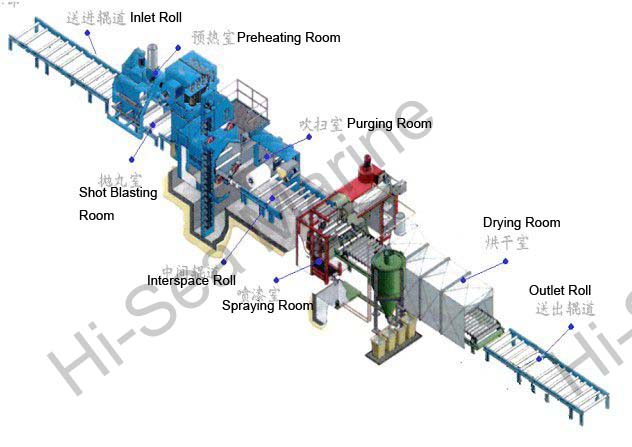

SXY series steel peening houses are comprised of cross in-feed transverse conveying unit (option), in-feed conveying rollers, shot blasting system, dust removing system, painting system, drying system, organic gas and paint mist treatment device, out-feed conveying system cross out-feed transverse conveying unit (option) and electrical system and so on. This equipment is mainly used to do shot blasting to steel plate / profiles to get a clean surface of Sa2.5 with certain roughness. After shot blasting, the painting system will paint anti-rust coating layer on steel. This ensures no second pollution during processing.

The whole line of this production line is 58mtr.s. It is controlled by PLC electrical controller.

Technical Parameters:

| Model | SXY2500 | SXY3000 | SXY3500 | SXY4000 | SXY4500 | SXY5000 | |

| Size (W¡ÁT¡ÁL) | 2500x60x12000mm | 3000x60x12000mm | 3500¡Á60¡Á12000mm | 4000¡Á60¡Á12000mm | 4500¡Á60¡Á12000mm | 5000¡Á60x12000mm | |

| Shot blasting system | Max loading | 1.5t/m | 2 t/m | 2t/m | 2t/m | 2t/m | 3t/m |

| Working speed | 1.0-3.0m/min | 1.0-3.0m/min | 1.0-3.0m/min | 1.0-3.0m/min | 1.0-3.0m/min | 1.0-3.0m/min | |

| Blasting volume | 350kg/min¡Á6 | 350kg/min¡Á6 | 400kg/min¡Á8 | 400kg/min¡Á8 | 480kg/min¡Á8 | 480kg/min¡Á8 | |

| Power | 22kw¡Á6 | 22kw¡Á6 | 30kw¡Á8 | 30kw¡Á8 | 37kw¡Á8 | 37kw¡Á8 | |

| Delivery capacity | 126t/h | 126t/h | 192t/h | 192 t/h | 230t/h | 230t/h | |

| Lifting capacity | 126t/h | 126t/h | 192t/h | 192 t/h | 230t/h | 230t/h | |

| Separating capacity | 126t/h | 126t/h | 192t/h | 192 t/h | 230t/h | 230t/h | |

| Rolling brush size | 900mm | 900mm | 900mm | 900mm | 900mm | 900mm | |

|

Shots cleaning off air blower |

9-19No.5A 15kw¡Á2 |

9-19No.5A 15kw¡Á2 |

9-19No.5A 15kw¡Á2 |

9-19NO.5.6A 18.5kw¡Á2 |

9-19NO.5.6A 18.5kw¡Á2 |

9-19NO.5.6A 18.5kw¡Á2 |

|

|

Air volume for dust collector |

32000 m3/h | 32000 m3/h | 38000 m3/h | 45000 m3/h | 45000 m3/h | 45000 m3/h | |

| Painting system |

Paint pump Pressure ratio Pressure |

GRACO 32£º1 0.6MPa |

GRACO 32£º1 0.6MPa |

GRACO 45:1 0.6MPa |

GRACO 45:1 0.6MPa |

GRACO 45:1 0.6MPa |

GRACO 45:1 0.6MPa |

|

Spray gun Quantity Moving speed |

206-513 2 20 -50m/min |

206-513 2 20 -50m/min |

206-513 4 20 -50m/min |

206-513 4 20 -50m/min |

206-513 4 20 -50m/min |

206-513 4 20 -50m/min |

|

|

Paint mist purity Blower |

Filter paper 7.5kw |

Filter paper 11kw |

Filter paper 15kw |

Filter paper 15kw |

Filter paper 15kw |

Filter paper 15kw |

|

| Drying system |

Temperature in chamber |

40-70¡æ | 40-70¡æ | 40-70¡æ | 40-70¡æ | 40-70¡æ | 40-70¡æ |

| Drying type | Heat air | Heat air | Heat air | Heat air | Heat air | Heat air | |

| Heating | Electric heat | Electric heat | Electric heat | Electric heat | Electric heat | Electric heat | |

|

Air volume Power |

6950m3/h 3kw |

6950m3/h 3kw |

6950m3/h 3kw |

6950m3/h 3kw |

6950m3/h 3kw |

6950m3/h 3kw |

|

| Surface quality | Sa2.5 | Sa2.5 | Sa2.5 | Sa2.5 | Sa2.5 | Sa2.5 | |

| Total power | 450KW | 450KW | 558kw | 558kw | 600KW | 612KW | |