Steel Plate Shot Blasting Painting Machine System

[Search Related Products]

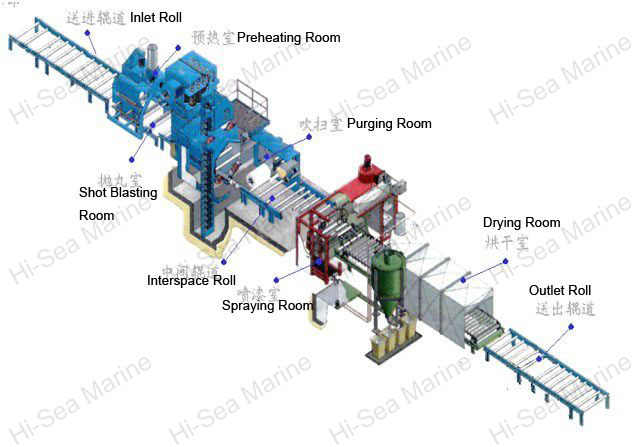

Steel Plate Shot Blasting Painting Machine System

Model: SXY3000-6

SXY3000 steel plate shot blasting painting machine is comprised of cross in-feed transverse conveying unit (option), in-feed conveying rollers, shot blasting system, dust removing system, painting system, drying system, organic gas and paint mist treatment device, out-feed conveying system cross out-feed transverse conveying unit (option) and electrical system and so on. This equipment is mainly used to do shot blasting to steel plate / profiles to get a clean surface of Sa2.5 with certain roughness. After shot blasting, the painting system will paint anti-rust coating layer on steel. This ensures no second pollution during processing.

The whole line of this production line is 58mtr.s. It is controlled by PLC electrical controller.

Main Technical parameters:

1. Size of blasting jobs

Name

Unit

Technical Data

Steel Plate

Thickness

mm

6~60

Width

mm

3000

Length

mm

3000~15000

Steel Profile

Height

mm

300

Length

mm

3000~15000

2. Size of blasting chamber open

|

Name |

Unit |

Technical Data |

|

Width |

mm |

3200 |

|

Height |

mm |

500 |

3. General Parameters

Name

Unit

Technical Data

Max loading of conveying rollers

t/m

1.5

Delivery speed

m/min

0.5~5

Working speed for steel plate

m/min

0.5~2.5

Working speed for steel profile

m/min

0.5~1.5

Annual output

t

50000 (250 working days, 8 hours / shift)

Surface quality

Sa2.5 GB8923-88

Paint film Thickness

¦Ìm

15~25

Temperature in drying chamber

¡æ

40-70

Compressed air consumption

cbm/h

6

Mpa

0.4~0.8

Dust Emission density

mg/cbm

80

Noise of whole equipment

dB

¡Ü85

Power of whole line

kw

About 395

Size of whole line

Refer to general drawing

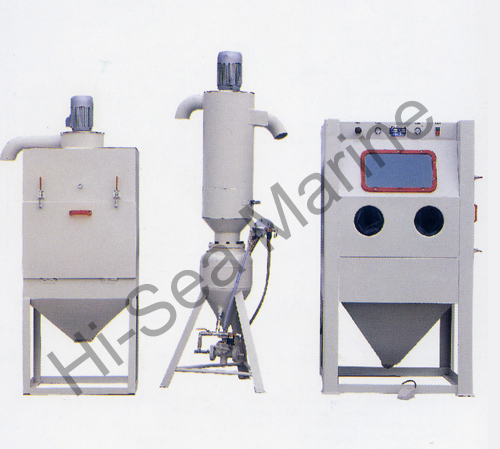

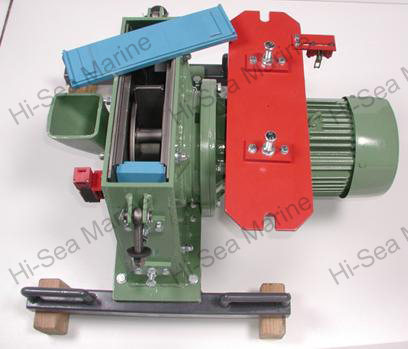

Part Detail Pictures: