YCB Marine Circular Gear Pump

[Search Related Products]

Applications:

¡ô YCB Series Circular Gear Pump applies to deliviering non-corrosive lubricating or equivalent liquid without solid particles and fibres at temperature below 300¡æand with the viscosity of 5¡Á10-6~51.5¡Á10-3m2/s (5~1500cSt). It applies to hydraulic System, too.

Reducing the speed, the marine pump can delivery the liquid that viscosity can be up to 5¡Á104cSt.

¡ô YCB Series Circular Gear Pump can give performance as transfer pump or booster pump in oil delivery system, and fuel pump for delivery pressurization and injection in fuel supply system. It can be also applied as hydraulic pump supplying hydraulic power in hydraulic system and in all industry fields as lubricating pump.

¡ô YCB series circular gear pumps are mainly composed of gears, axles, pump body, pump cover, bearing sleeves and axle-end seal, etc. The gears are adopt double circular teeth shape, which makes the gears less wear on gear surface, stable revolution, low noise, long service life and high efficiency. due to no sliding on the teeth during gear fallingin. This kind of pump has got rid of traditional design and come into a new decade in design and application.

¡ô The pump is designed with safety valve for protection against overload. The full return flow pressure is 1.5 times higher than the rated exhaust pressure of the pump. It can be adjusted within the allowance of exhaust pressure range according to circumstance. But please note the safety valve can¡¯t be applied as pressure-reducing valve for long time. You may install pressure reducing valve separately on pipe-line if needed.

¡ô There are two kinds of axle-end seals, mechanical seal and packing seal, which can be chosen according to the client¡¯requirement or application circumstance.

The direction of rotation is clockwise viewed from coupling end .

Performance Parameter

|

Model |

Capacity (m3/h) |

Speed |

Discharge pressure |

NPSHr (m) |

Efficiency |

Electric motor |

|||

|

Frequency (Hz) |

Power (kw) |

Model |

|||||||

|

YCB0.6-0.6 |

0.6 |

910 |

0.6 |

5.5 |

60 |

50 |

0.75 |

Y90S-6 |

|

|

1.0 |

1390 |

50 |

0.75 |

Y80L2-4 |

|||||

|

0.7 |

1130 |

60 |

0.75 |

Y90S-6 |

|||||

|

1.2 |

1710 |

60 |

0.75 |

Y80L2-4 |

|||||

|

YCB0.6-2.5 |

0.6 |

910 |

2.5 |

7.0 |

70 |

50 |

1.1 |

Y90L-6 |

|

|

1.0 |

1400 |

50 |

1.5 |

Y90L-4 |

|||||

|

0.7 |

1130 |

60 |

1.1 |

Y90L-6 |

|||||

|

1.2 |

1710 |

60 |

1.1 |

Y90S-4 |

|||||

|

YCB1.6-0.6 |

1.6 |

910 |

0.6 |

5.5 |

63 |

50 |

0.75 |

Y90S-6 |

|

|

2.5 |

1400 |

50 |

1.1 |

Y90S-4 |

|||||

|

1.9 |

1130 |

60 |

1.1 |

Y90L-6 |

|||||

|

3.0 |

1710 |

60 |

1.5 |

Y90L-4 |

|||||

|

YCB1.6-2.5 |

1.6 |

940 |

2.5 |

7.0 |

71 |

50 |

2.2 |

Y112M-6 |

|

|

2.5 |

1440 |

50 |

4 |

Y112M-4 |

|||||

|

1.9 |

1150 |

60 |

2.2 |

Y112M-6 |

|||||

|

3.0 |

1750 |

60 |

4 |

Y112M-4 |

|||||

|

YCB3.3-0.6 |

3.3 |

940 |

0.6 |

5.0 |

60 |

50 |

1.5 |

Y100L-6 |

|

|

5.0 |

1420 |

50 |

2.2 |

Y100L1-4 |

|||||

|

4.0 |

1150 |

60 |

1.5 |

Y100L-6 |

|||||

|

6.0 |

1730 |

60 |

2.2 |

Y100L1-4 |

|||||

|

YCB3.3-2.5 |

3.3 |

960 |

2.5 |

7.0 |

72 |

50 |

5.5 |

Y132M2-6 |

|

|

5.0 |

1440 |

50 |

7.5 |

Y132M-4 |

|||||

|

4.0 |

1170 |

60 |

4 |

Y132M1-6 |

|||||

|

6.0 |

1750 |

60 |

7.5 |

Y132M-4 |

|||||

|

YCB4-0.6 |

4.0 |

940 |

0.6 |

5.0 |

60 |

50 |

1.5 |

Y100L-6 |

|

|

6.0 |

1420 |

50 |

2.2 |

Y100L1-4 |

|||||

|

4.8 |

1150 |

60 |

2.2 |

Y112M-6 |

|||||

|

7.2 |

1730 |

60 |

3 |

Y100L2-4 |

|||||

|

YCB4-2.5 |

4.0 |

960 |

2.5 |

7.0 |

72 |

50 |

5.5 |

Y132M2-6 |

|

|

6.0 |

1440 |

50 |

7.5 |

Y132M-4 |

|||||

|

4.8 |

1170 |

60 |

5.5 |

Y132M-6 |

|||||

|

7.2 |

1750 |

60 |

7.5 |

Y132M-4 |

|||||

|

YCB8-0.6 |

8.0 |

960 |

0.6 |

5.0 |

61 |

50 |

3 |

Y132S-6 |

|

|

12.0 |

1440 |

50 |

5.5 |

Y132S-4 |

|||||

|

9.6 |

1170 |

60 |

4 |

Y132M1-6 |

|||||

|

14.4 |

1750 |

60 |

5.5 |

Y132S-4 |

|||||

|

YCB8-2.5 |

8.0 |

970 |

2.5 |

7.0 |

75 |

50 |

11 |

Y160L-6 |

|

|

12.0 |

1460 |

50 |

15 |

Y160L-4 |

|||||

|

9.6 |

1170 |

60 |

11 |

Y160L-6 |

|||||

|

14.4 |

1760 |

60 |

15 |

Y160L-4 |

|||||

|

YCB10-0.6 |

10.0 |

960 |

0.6 |

5.0 |

62 |

50 |

4 |

Y132M1-6 |

|

|

15.0 |

1440 |

50 |

5.5 |

Y132S-4 |

|||||

|

12.0 |

1170 |

60 |

5.5 |

Y132M2-6 |

|||||

|

18.0 |

1750 |

60 |

7.5 |

Y132M-4 |

|||||

|

YCB10-2.5 |

10.0 |

970 |

2.5 |

7.0 |

76 |

50 |

11 |

Y160L-6 |

|

|

15.0 |

1470 |

50 |

15 |

Y160L-4 |

|||||

|

12.0 |

1170 |

60 |

11 |

Y160L-6 |

|||||

|

18.0 |

1770 |

60 |

18.5 |

Y180M-4 |

|||||

|

YCB20-0.6 |

20.0 |

970 |

0.6 |

5.0 |

68 |

50 |

7.5 |

Y160M-6 |

|

|

24.0 |

1170 |

60 |

7.5 |

Y160M-6 |

|||||

|

YCB25-0.6 |

25.0 |

970 |

0.6 |

5.5 |

69 |

50 |

11 |

Y160L-6 |

|

|

30.0 |

1170 |

60 |

11 |

Y160L-6 |

|||||

|

YCB30-0.6 |

30.0 |

970 |

0.6 |

5.5 |

65 |

50 |

11 |

Y160L-6 |

|

|

36.0 |

1170 |

60 |

11 |

Y160L-6 |

|||||

|

YCB40-0.6 |

40.0 |

970 |

0.6 |

5.5 |

66 |

50 |

15 |

Y180L-6 |

|

|

48.0 |

1180 |

60 |

15 |

Y180L-6 |

|||||

|

YCB50-0.6 |

50.0 |

970 |

0.6 |

5.5 |

66 |

50 |

22 |

Y200L2-6 |

|

|

60.0 |

1180 |

60 |

22 |

Y200L2-6 |

|||||

|

YCB60-0.6 |

60.0 |

1470 |

0.6 |

5.5 |

65 |

50 |

22 |

Y180L-4 |

|

|

YCB80-0.6 |

80.0 |

980 |

0.6 |

5.5 |

65 |

50 |

30 |

Y205M-6 |

|

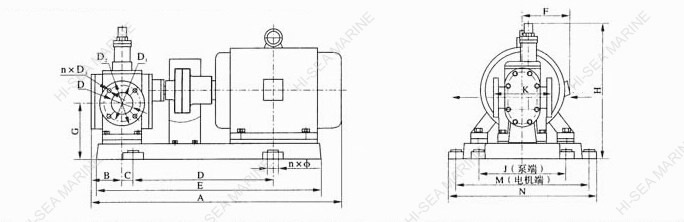

Structure

Photo

Our Certification