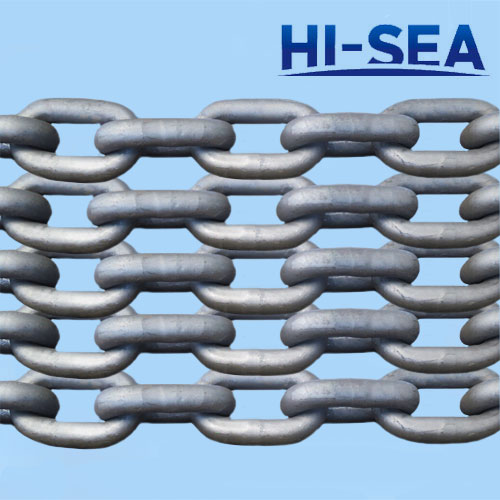

Offshore Mooring Chain

[Search Related Products]

Offshore Mooring Chain

Offshore mooring chains, different from common anchor chains, are widely used in oil drilling platforms and other offshore structures to fix the platfroms and avoid movement. Due to the work environment is very bad, the mooring chains should have high strength, good toughness, wear resistance, fatigue resistance, corrosion resistance etc..

Size: 34mm~162mm

Grade: R3, R3S, R4, R4S,R5

Material: Offshore Mooring Chain Steel

Accessories: Stud Links of Mooring Chains, Studless Links of Mooring Chains, Swivel, Swivel Shackle, Triangle Plate etc.

Application: Offshore Drilling Equipment, Mobile Offshore Oil Recovery Equipment, Floating Crane, Pipe-laying Ship etc.

Certificate: CCS, BV, LR, ABS, BKI, API etc.

Service: We supply standard and non-standard products. We can also customize the products according to your special requirements.

ABS,DNV Mooring Chains Metric Load Sheet(Chain Dia. Unit: mm; Load Unit: kN)

|

Chain Diameter |

R3 |

R3S |

R4 |

|||||

|

Stud/Studless Pull Load |

Breaking Load |

Studless Link Pull Load |

Stud Link Pull Load |

Breaking Load |

Studless Link Pull Load |

Stud Link Pull Load |

Breaking Load |

|

|

50 |

1560 |

2230 |

1740 |

1800 |

2490 |

1920 |

2160 |

2740 |

|

52 |

1681 |

2403 |

1875 |

1940 |

2683 |

2069 |

2327 |

2953 |

|

54 |

1806 |

2581 |

2014 |

2083 |

2882 |

2222 |

2500 |

3171 |

|

56 |

1934 |

2764 |

2157 |

2231 |

3086 |

2380 |

2677 |

3396 |

|

58 |

2066 |

2953 |

2304 |

2384 |

3297 |

2543 |

2860 |

3628 |

|

60 |

2202 |

3147 |

2456 |

2541 |

3514 |

2710 |

3049 |

3867 |

|

62 |

2342 |

3347 |

2612 |

2702 |

3737 |

2882 |

3242 |

4112 |

|

64 |

2485 |

3552 |

2771 |

2867 |

3966 |

3058 |

3440 |

4364 |

|

66 |

2632 |

3762 |

2935 |

3036 |

4200 |

3239 |

3644 |

4622 |

|

68 |

2782 |

3977 |

3103 |

3210 |

4440 |

3424 |

3852 |

4886 |

|

70 |

2936 |

4196 |

3274 |

3387 |

4686 |

3613 |

4065 |

5156 |

|

73 |

3173 |

4535 |

3539 |

3661 |

5064 |

3905 |

4393 |

5572 |

|

76 |

3417 |

4885 |

3812 |

3943 |

5454 |

4206 |

4731 |

6002 |

|

78 |

3584 |

5124 |

3998 |

4136 |

5721 |

4411 |

4963 |

6295 |

|

81 |

3841 |

5490 |

4284 |

4432 |

6130 |

4727 |

5318 |

6746 |

|

84 |

4104 |

5866 |

4578 |

4735 |

6550 |

5051 |

5682 |

7028 |

|

87 |

4374 |

6252 |

4879 |

5047 |

6981 |

5383 |

6056 |

7682 |

|

90 |

4651 |

6648 |

5187 |

5366 |

7423 |

5724 |

6439 |

8168 |

|

92 |

4838 |

6916 |

5397 |

5583 |

7723 |

5955 |

6699 |

8498 |

|

95 |

5125 |

7326 |

5717 |

5914 |

8180 |

6308 |

7096 |

9002 |

|

97 |

5320 |

7604 |

5934 |

6138 |

8491 |

6547 |

7366 |

9343 |

|

100 |

5616 |

8028 |

6264 |

6480 |

8964 |

6912 |

7776 |

9864 |

Note: the above parameters is only one part. If you want to know more detail information, please feel free to contact us.

Testing Load of Mooring Chain Accessories

|

Load(KN) |

R3 Stud Chian |

R3S Stud Chain |

R4 Stud Chain |

|

Pull Load(PL) |

0.0156d²(44-0.08d) |

0.0180d²(44-0.08d) |

0.0216d²(44-0.08d) |

|

Breaking Load(BL) |

0.0223d²(44-0.08d) |

0.0249d²(44-0.08d) |

0.0274d²(44-0.08d) |

|

Load(KN) |

R3 Studless Chian |

R3S Studless Chain |

R4 Studless Chain |

|

Pull Load(PL) |

0.0156d²(44-0.08d) |

0.01743d²(44-0.08d) |

0.01918d²(44-0.08d) |

|

Breaking Load(BL) |

0.0223d²(44-0.08d) |

0.0249d²(44-0.08d) |

0.0274d²(44-0.08d) |

Note: this load sheet refers to ABS rules and DNV rules, all loading data included in the sheet shall be calculated according to relevant formulas.

Mechanical Properities of Mooring Chains

|

Grade |

Yield Point (N/mm²,min) |

Tensile Strength (N/mm²,min) |

Elongation (%,min) |

Reduction of Area (%,min) |

Impact Test(V-notch ) |

||

|

Test Temperature (¡æ) |

Impact (J,min) |

||||||

|

Base Part |

Weld Part |

||||||

|

API Spec 2F (ORQ) |

___ |

641 |

17 |

40 |

0 |

58 |

49 |

|

-15 |

40 |

36 |

|||||

|

ABS/RQ3 DNV/NVR3 |

410 |

690 |

17 |

50 |

0 |

60 |

50 |

|

-20 |

40 |

30 |

|||||

|

ABS/RQ3S DNV/NVR3S |

490 |

770 |

15 |

50 |

0 |

65 |

53 |

|

-20 |

45 |

43 |

|||||

|

ABS/RQ4 DNV/NVR4 |

580 |

860 |

12 |

50 |

-20 |

50 |

36 |

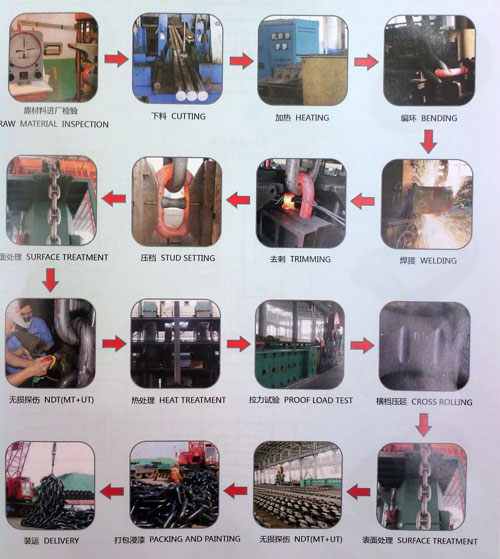

Manufacturing Process of Mooring Chain

1. Raw Material Inspection ¡ú 2. Bar Cutting ¡ú 3. Bar Heating ¡ú 4. Bending ¡ú 5. Welding ¡ú 6. Trimming ¡ú 7. Stud Inserting ¡ú 8. Surface Treatment ¡ú 9. NDT(MT+UT) ¡ú 10. Heat Treatment ¡ú 11. Proof Load Test ¡ú 12. Cross Rolling ¡ú 13. Surface Treatment ¡ú 14. NDT(MT+UT) ¡ú 15. Packing and Painting ¡ú 16. Delivery