Marine Deck Equipment

[Search Related Products]

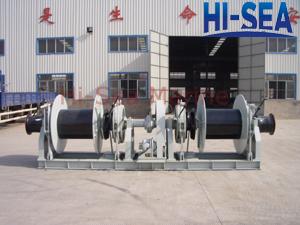

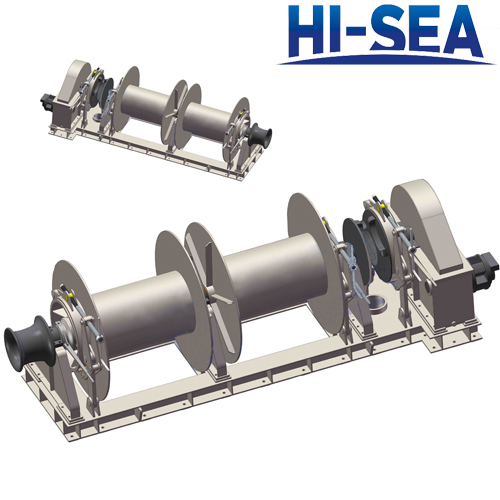

Marine Windlass

Whatever your anchor application, Hi-Sea Marine's line of anchor windlass offers a variety of styles and sizes to handle it. Our anchor windlass winches are designed for up to 160mm chain with a range of drive options available. Standard features include fabricated steel construction, gears hardened to exceed working load requirements, cluthed and braked drum and corrosion resistance. Electric or hydraulic drives are available along with warping heads. We can modify windlasses to suit your application and special operation requirements.

Hi-Sea Marine's anchor windlass winches have rugged design, heavy duty split bronze bearings and amply dimensioned brakes. The operating mechanism for brake and cluthes are designed for easy and safe manual operating, but may also be remotely operating by hydraulic cylinders. The brakes are easily adjustable, and all transfer of external forces to the deck construction is by the foundation bolts. The winch design provides easy access to all points for lubrication and inspections.

Main technical specification

| Chain Dia.(mm) | Working Load(kN) | Supporting Load(kN) | Working Speed(m/min) | Warping Load(kN) | Motor Power(kW) | Motor Power(kW) |

| 12.5 | 5.9 | 30 | ¡Ý9 | 5 | 3/1.2 | |

| 14/16/17.5 | 8.3/10.9/13.0 | 51/67/80 | ¡Ý9 | 8 | 5.5 | 4.3/1.7 |

| 19/20.5/22 | 15.3/17.9/20.6 | 95/110/126 | ¡Ý9 | 10 | 7.5 | 8.5/3.5 |

| 24/26 | 24.5/28.7 | 149/175 | ¡Ý9 | 20 | 11 | 8.5/3.5 |

| 28/30 | 33.3/38.3 | 202/231 | ¡Ý9 | 30 | 15 | 11/11/7.5 |

| 32/34/36 | 43.5/49.1/55.1 | 261/294/329 | ¡Ý9 | 30 | 22 | 16/16/11 |

| 38/40/42 | 61.4/68.0/75.0 | 365/402/442 | ¡Ý9 | 40 | 30 | 22/22/16 |

| 44/46/48 | 82.3/89.9/97.9 | 483/526/570 | ¡Ý9 | 50 | 37 | 30/30/22 |

| 50/52/54 | 106.3/114.9/123.9 | 617/664/713 | ¡Ý9 | 50 | 45 | 30/30/22 |

| 56/58/60 | 133.3/143.0/153 | 764/816/870 | ¡Ý9 | 60 | 55 | 45/45/30 |

| 62/64 | 163.4/174.1 | 925/982 | ¡Ý9 | 80 | 55 | 45/45/30 |

| 66/68 | 185.1/196.5 | 1040/1098 | ¡Ý9 | 100 | 75 | 45/45/30 |

| 70/73 | 208.3/226.5 | 1160/1254 | ¡Ý9 | 100 | 75 | 60/60/45 |

| 76/78 | 245.5/258.6 | 1350/1416 | ¡Ý9 | 125 | 90 | 60/60/45 |

| 81/84 | 311.7/335.2 | 2171/2320 | ¡Ý9 | 140 | 110 | 75/75/36 |

| 87/90 | 359.5/384.8 | 2473/2629 | ¡Ý9 | 150 | 120 | 75/75/36 |

| 92/95 | 402.0/428.7 | 2735/2898 | ¡Ý9 | 200 | 130 | 85/85/64 |

| 97/100 | 446.9/475.0 | 2995/3162 | ¡Ý9 | 250 | 150 | 100/100/50 |

| 05/107 | 523.7/543.8 | 3612/3750 | ¡Ý9 | 300 | 180 | 110/110/55 |

| 112/114 | 595.8/617.3 | 4109/4228 | ¡Ý9 | 350 | 200 | 132/132/66 |

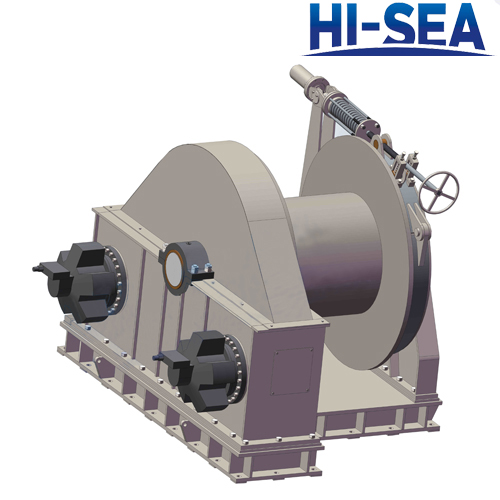

Have a rugged design, heavy duty split bronze bearings and amply dimensioned brakes. The operating mechanisms for brakes and cluthes are desgined for easy and safe manual operation, but may also be remotely operated by hydraulic cylinders. The brakes are easily adjustable, and all transferred of external forces to the deck construction is via the foundation bolts. No special welded steel constructions, more flexible for variations winch may occur. This arrangement also has the benefit of making transportation of the winches simpler and less expensive. The manual cluth operating is with spindles for winches for winches from 16 tonnes pulling power and upwards. The marine winch design provides easy access to all points for lubrication and inspection. Gear may be delivered as open type with steel protection cover, or as totally enclosed gears with oil bath.

Main technical specification

|

Rated Pull(kN) |

Rated Speed(m/min) |

Drum Capacity(m) |

Motor Power(kW) |

Motor Power(kW) |

|

5 |

¡Ý12 |

§¶8§ç100 |

3/1.2 |

|

|

10 |

¡Ý12 |

§¶10§ç150 |

5.5 |

4.3/1.7 |

|

20 |

¡Ý12 |

§¶15§ç150 |

11 |

8.5/3.5 |

|

30 |

¡Ý15 |

§¶17§ç150 |

15 |

11/11/7.5 |

|

40 |

¡Ý15 |

§¶18§ç150 |

22 |

16/16/11 |

|

50 |

¡Ý15 |

§¶20.5§ç150 |

30 |

22/22/16 |

|

75 |

¡Ý15 |

§¶26§ç200 |

45 |

30/30/22 |

|

80 |

¡Ý15 |

§¶26§ç200 |

45 |

30/30/22 |

|

100 |

¡Ý15 |

§¶30§ç200 |

45 |

45/45/30 |

|

125 |

¡Ý15 |

§¶30§ç200 |

75 |

45/45/30 |

|

160 |

¡Ý15 |

§¶32§ç250 |

75 |

60/60/45 |

|

200 |

¡Ý9.6 |

§¶41§ç250 |

75 |

60/60/45 |

|

250 |

¡Ý9.6 |

§¶44.5§ç250 |

90 |

60/60/45 |

|

315 |

¡Ý7.8 |

§¶52§ç250 |

90 |

60/60/45 |

|

400 |

¡Ý7.8 |

§¶56§ç250 |

110 |

85/85/64 |

|

450 |

¡Ý7.8 |

§¶56§ç250 |

110 |

85/85/64 |

|

500 |

¡Ý7.8 |

§¶58§ç250 |

110 |

85/85/64 |

|

560 |

¡Ý6 |

§¶64§ç250 |

132 |

85/85/64 |

|

600 |

¡Ý6 |

§¶64§ç250 |

132 |

85/85/64 |

|

650 |

¡Ý6 |

§¶70§ç250 |

132 |

85/85/64 |

|

1000 |

¡Ý4 |

§¶85§ç250 |

132 |

85/85/64 |

|

1200 |

¡Ý4 |

§¶95§ç250 |

160 |

120/120/90 |

|

1500 |

¡Ý4 |

§¶95§ç250 |

200 |

150/150/72 |

|

1800 |

¡Ý4 |

§¶95§ç250 |

250 |

150/150/72 |

|

2000 |

¡Ý4 |

§¶100§ç250 |

270 |

180/180/135 |

|

Chain Dia.(mm) |

Working Load(kN) |

Working Speed(m/mim) |

Warping Load(kN) |

Warping Speed(m/min) |

Wire Dia.(mm) |

Motor Power(kW) |

|

11/14 |

5.9/7.4 |

¡Ý12 |

5 |

¡Ý10 |

§¶11 |

3/1.2 |

|

16/17.5 |

10.9/13.0 |

¡Ý12 |

8 |

¡Ý10 |

§¶13 |

4.3/1.7 |

|

19/22 |

15.3/20.6 |

¡Ý12 |

10 |

¡Ý10 |

§¶13 |

6/2.5 |

|

24/26 |

24.5/28.7 |

¡Ý9 |

20 |

¡Ý8.5 |

§¶15 |

7.5/7.5/5 |

|

28/30 |

33.3/38.3 |

¡Ý9 |

30 |

¡Ý8.5 |

§¶17.5 |

16/16/11 |

|

32/34/36 |

43.5/49.1/55.1 |

¡Ý9 |

30 |

¡Ý8.5 |

§¶17.5 |

16/16/11 |

|

38/40/42 |

61.4/68.0/75.0 |

¡Ý9 |

50 |

¡Ý8.5 |

§¶20.5 |

22/22/16 |

|

44/46/48 |

82.3/89.9/97.9 |

¡Ý9 |

50 |

¡Ý8 |

§¶26 |

30/30/22 |

|

50/52/54 |

106.3/114.9/123.9 |

¡Ý9 |

60 |

¡Ý8 |

§¶26 |

30/30/22 |

|

56/58/60 |

133.3/143.0/153.0 |

¡Ý9 |

60 |

¡Ý8 |

§¶26 |

45/45/30 |

Taking landing working condition as design basis, marine crane is specially designed for various cargo ships.

The crane can be installed in the middle of ships or bow sides.

The crane adopts wire cable amplitude variation, planetary reducer lift winch, and rotation driving mechanism, and has reliable operation, durability, convenient maintenance and other characteristics.

-

This crane can be equipped with:

-

Cab air-conditioning system

-

Grab system

-

Suspension arm projection lamp

-

Touch screen display function

|

Type |

Safety Load(kN) |

Max Working Radius(m) |

Min Working Radius(m) |

Hoisting Speed(m/min) |

Slewing Speed(r/min) |

Luffing Time(s) |

Slewing Angle(¡ã) |

Permission List/Trim(¡ã) |

Hoisting Height(m) |

Power(kW) |

|

YQ1 |

10 |

6~12 |

1.3~2.6 |

15 |

1 |

60 |

360 |

2¡ã/5¡ã |

30 |

7.5 |

|

YQ1.5 |

15 |

8~14 |

1.7~3 |

15 |

1 |

60 |

360 |

2¡ã/5¡ã |

30 |

11 |

|

YQ2 |

20 |

5~15 |

1.1~3.2 |

15 |

1 |

60 |

360 |

2¡ã/5¡ã |

30 |

15 |

|

YQ3 |

30 |

8~18 |

1.7~3.8 |

15 |

0.9 |

70 |

360 |

2¡ã/5¡ã |

30 |

22 |

|

YQ5 |

50 |

12~20 |

2.5~4.2 |

15 |

0.75 |

80 |

360 |

2¡ã/5¡ã |

30 |

37 |

|

YQ8 |

80 |

12~20 |

2.5~4.2 |

15 |

0.75 |

100 |

360 |

2¡ã/5¡ã |

30 |

55 |

|

YQ10 |

100 |

12~20 |

2.5~4.2 |

15 |

0.75 |

110 |

360 |

2¡ã/5¡ã |

30 |

75 |

|

YQ15 |

150 |

12~20 |

2.5~4.2 |

15 |

0.6 |

110 |

360 |

2¡ã/5¡ã |

30 |

90 |

|

YQ20 |

200 |

16~25 |

3.2~5.3 |

15 |

0.6 |

120 |

360 |

2¡ã/5¡ã |

35 |

75*2 |

|

YQ25 |

250 |

20~30 |

3.2~6.3 |

15 |

0.5 |

130 |

360 |

2¡ã/5¡ã |

40 |

90*2 |

|

YQ30 |

300 |

30 |

3.2~6.3 |

15 |

0.4 |

140 |

360 |

2¡ã/5¡ã |

40 |

90*2 |

|

YQ35 |

350 |

20~35 |

4.2~7.4 |

15 |

0.5 |

150 |

360 |

2¡ã/5¡ã |

45 |

110*2 |

|

YQ40 |

400 |

20~35 |

4.2~7.4 |

15 |

0.5 |

150 |

360 |

2¡ã/5¡ã |

45 |

140*2 |

|

YQ45 |

450 |

25~40 |

5.3~8.5 |

15 |

0.45 |

160 |

360 |

2¡ã/5¡ã |

50 |

140*2 |

|

YQ50 |

500 |

25~40 |

5.3~8.5 |

15 |

0.45 |

170 |

360 |

2¡ã/5¡ã |

50 |

165*2 |