JIS F 2005-1975 Closed Chock

[Search Related Products]

JIS F 2005-1975 Closed Chock

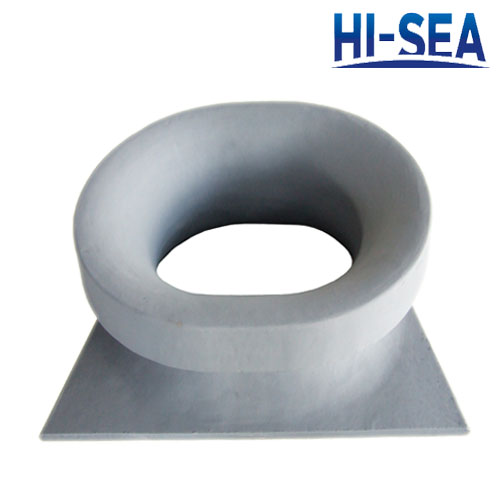

Closed chock is one form of mooring chock which used to guide the mooring ropes. JIS F-2005 closed chock is made according to marine standard of Japanese Standard Association. JIS F-2005 is made of cast steel. Its surface is galvanized, polished and painted to be smooth,which can reduce the friction of the rope. We can also produce the customized chocks for your specific need. If you¡¯re interested in our mooring chocks, please feel free to contact us.

Specification :

Model Type: JIS F 2005-1975 Closed Chock

Material: Cast Steel

Nominal Size: 100mm~200mm, 250mm~500mm

Weight: 3.7kg~24kg, 48kg~232kg

Standard: JIS F 2005-1975

Certificate: CCS,DNV,ABS,BV,LR,RS,KR

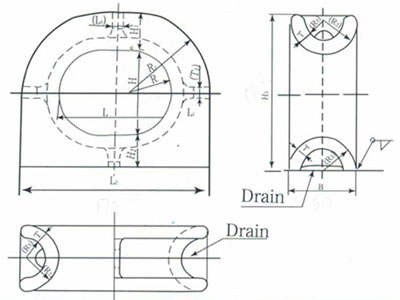

Drawing 1 of JIS F 2005-1975:

Unit:mm

|

Nominal Size |

L |

L1 |

L2 |

B |

H |

H1 |

H2 |

H3 |

R |

R1 |

T |

(T1) |

(R2) |

(R3) |

Welding Length |

Calculated Mass(kg) |

Dia of Applicable Rope for Reference |

||

|

Wire Rope |

Hemp Rope |

Fiber Rope |

|||||||||||||||||

|

100 |

100 |

35 |

170 |

60 |

76 |

141 |

30 |

35 |

38 |

73 |

12 |

(10) |

(30) |

(18) |

7 |

3.7 |

14(6¡Á12) |

24 |

18 |

|

150 |

150 |

50 |

250 |

90 |

110 |

205 |

45 |

50 |

55 |

105 |

16 |

(12) |

(45) |

(29) |

8 |

10.5 |

16(6¡Á12) |

30 |

22 |

|

200 |

200 |

70 |

370 |

120 |

150 |

280 |

60 |

70 |

75 |

145 |

20 |

(16) |

(60) |

(40) |

9 |

24.0 |

18(6¡Á12) |

40 |

28 |

Note:1. THE DIMENSION IN () IS ONLY FOR REFERENCE.

2. FOR APPLICABLE ROPES, REFERENCE IS MADE TO NO.4(4¡Á24) OF JIS G 3525, FOR HEMP ROPE, TO CLASS L, GROUP 1 OF JIS L 2701.

3. SURFACE IN CONTACT WITH THE ROPE IN USE SHALL BE POLISHED SMOOTHLY.

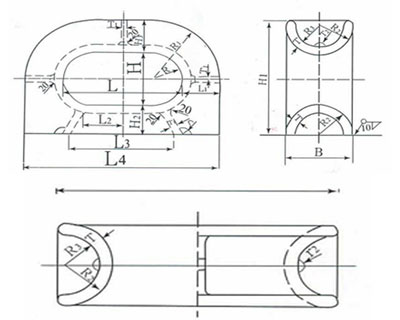

Drawing 2 of JIS F 2005-1975:

Unit:mm

|

Nominal Size |

L |

L1 |

L2 |

L3 |

L4 |

B |

H |

H1 |

H2 |

H3 |

R |

R1 |

R2 |

R3 |

r1 |

r2 |

T |

T1 |

Calculated Mass(kg) |

Dia of Applicable Rope in reference |

|

|

Wire Rope |

Hemp Rope |

||||||||||||||||||||

|

250 |

250 |

92 |

100 |

250 |

434 |

160 |

200 |

372 |

80 |

92 |

100 |

192 |

80 |

56 |

20 |

15 |

24 |

20 |

48 |

20(6¡Á12) |

50 |

|

300 |

300 |

114 |

110 |

300 |

528 |

200 |

250 |

464 |

100 |

114 |

125 |

239 |

100 |

72 |

25 |

20 |

28 |

22 |

83 |

22.4(6¡Á12) |

60 |

|

350 |

350 |

125 |

125 |

350 |

600 |

220 |

250 |

485 |

110 |

125 |

125 |

250 |

110 |

80 |

30 |

20 |

30 |

22 |

103 |

24(6¡Á24) |

70 |

|

400 |

400 |

136 |

135 |

370 |

672 |

240 |

250 |

506 |

120 |

136 |

125 |

261 |

120 |

88 |

30 |

20 |

32 |

25 |

136 |

26(6¡Á24) |

80 |

|

450 |

450 |

148 |

150 |

400 |

746 |

260 |

250 |

528 |

130 |

148 |

125 |

273 |

130 |

94 |

30 |

20 |

36 |

28 |

184 |

30(6¡Á24) |

85 |

|

500 |

500 |

160 |

175 |

450 |

820 |

280 |

250 |

550 |

140 |

160 |

125 |

185 |

140 |

100 |

30 |

20 |

40 |

30 |

232 |

35.5(6¡Á24) |

90 |

Note: 1. For applicable reference is made to NO.4 (6¡Á24) of JIS G 3525, for hemp rope to class 1, gruoup 1 of JIS L 2701.

2. Surface in contact with the rope in use shall be polished smoothly.